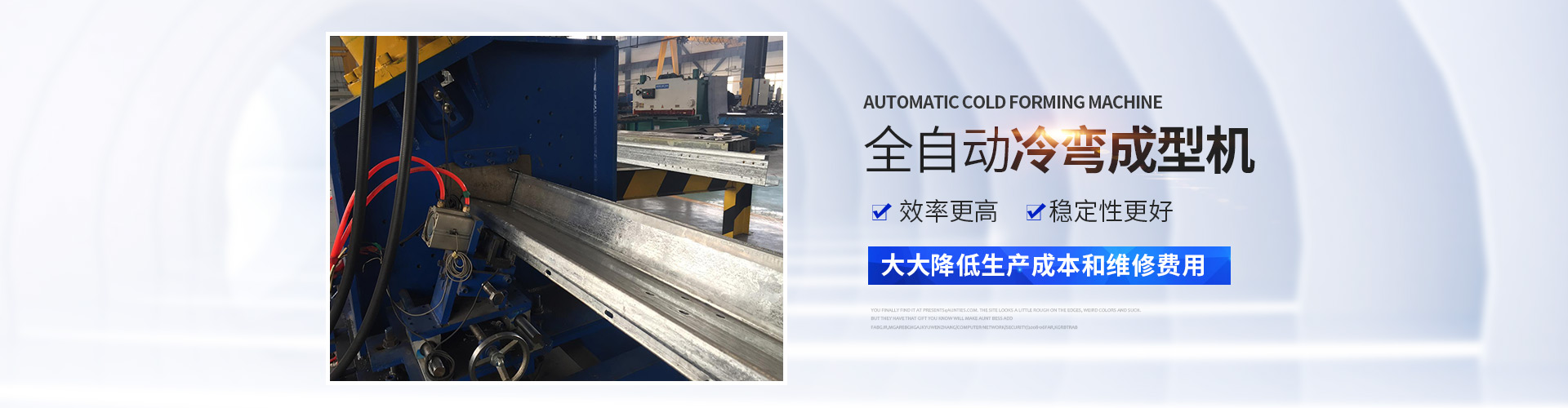

产品描述

消防栓箱箱体冷弯成型设备的制造对加工精度和设计能力有着较高的要求,我公司从事冷弯成型设备的制造近20年,有着丰富的制造经验。并且加工实力雄厚,售后服务完善。目前已成功向客户交付多台高质量的消防栓箱箱体一次成型设备,为客户创造出了更大的成本优势,为更好的开拓市场提供了有力**。

The manufacture of cold forming equipment for fire hydrant box has high requirements for machining precision and design ability. Our company is engaged in the manufacture of cold forming equipment for nearly 20 years and has rich manufacturing experience. And processing strength, perfect after-sales service. At present, we have successfully delivered a number of high-quality fire hydrant box molding equipment to customers, creating greater cost advantages for customers, and providing a strong guarantee for better development of the market.

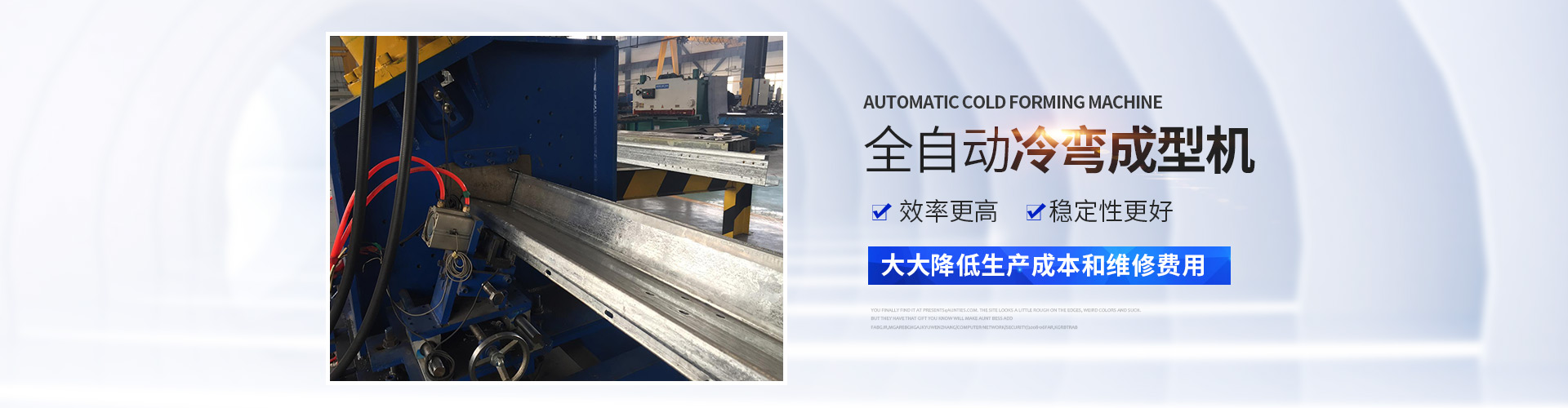

消防栓箱体冷弯一次成型设备主要实现的功能有:在线打孔、切角、折边成型、箱体折弯。相当于一条流水线,整个生产过程*人工参与中间环节,只需将带钢放置在开卷机上面并引料一次即可实现自动生产,设备的只要优势在于自动化程度高,对工人数量没有太多要求,并且生产速度快,每分钟可以为客户实现2个左右的箱体产量,每个班的产量还是比较惊人的。

The main functions of the fire hydrant box cold forming equipment are: on-line drilling, cutting angle, flanging, box bending. Equivalent to a assembly line, the whole production process does not need to participate in the intermediate link manually, it is only necessary to place the strip steel on the uncoiler and lead the material once to realize automatic production. The advantage of the equipment is that the degree of automation is high. There are no requirements for the number of workers, and the production rate is fast, can achieve about 2 boxes per minute for customers, the output per class or more amazing.

产品推荐