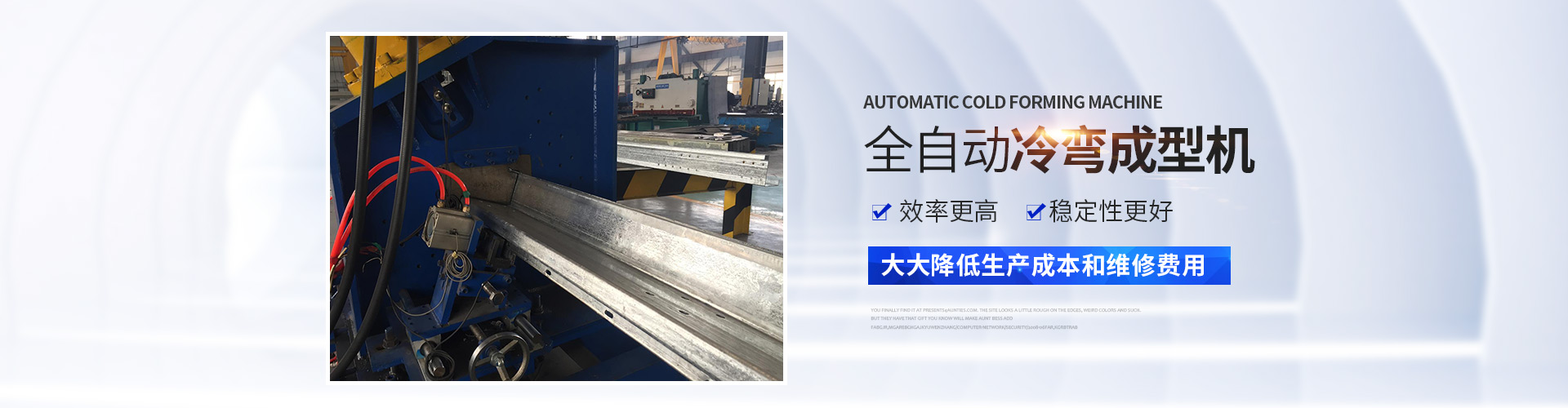

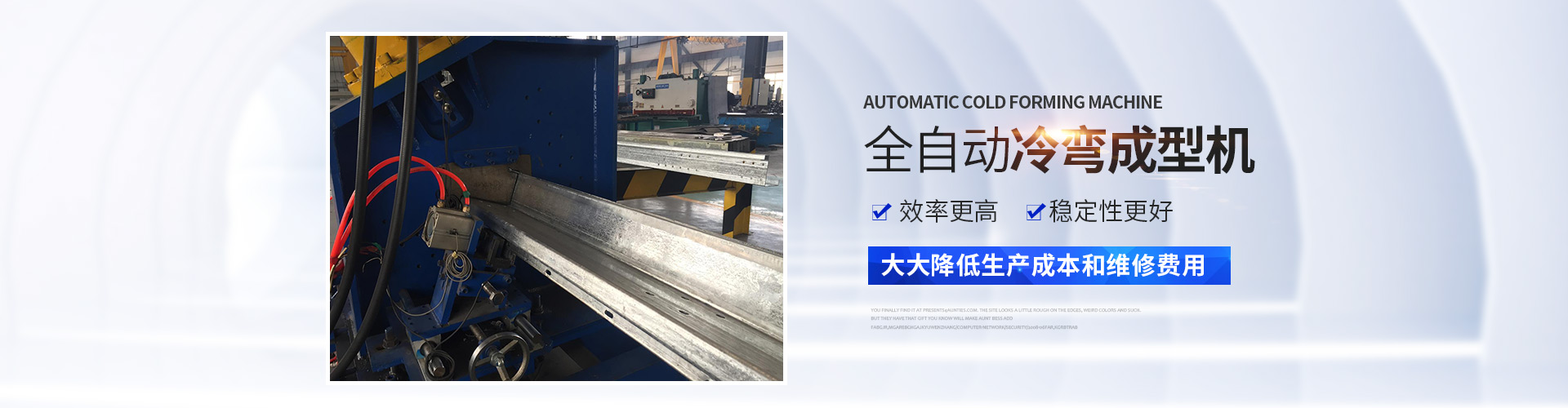

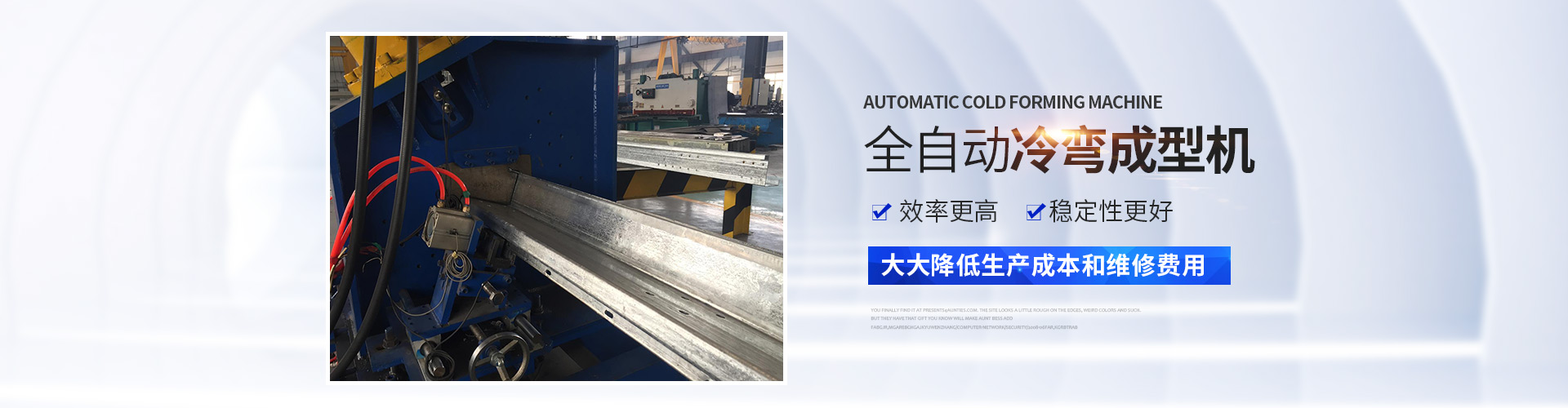

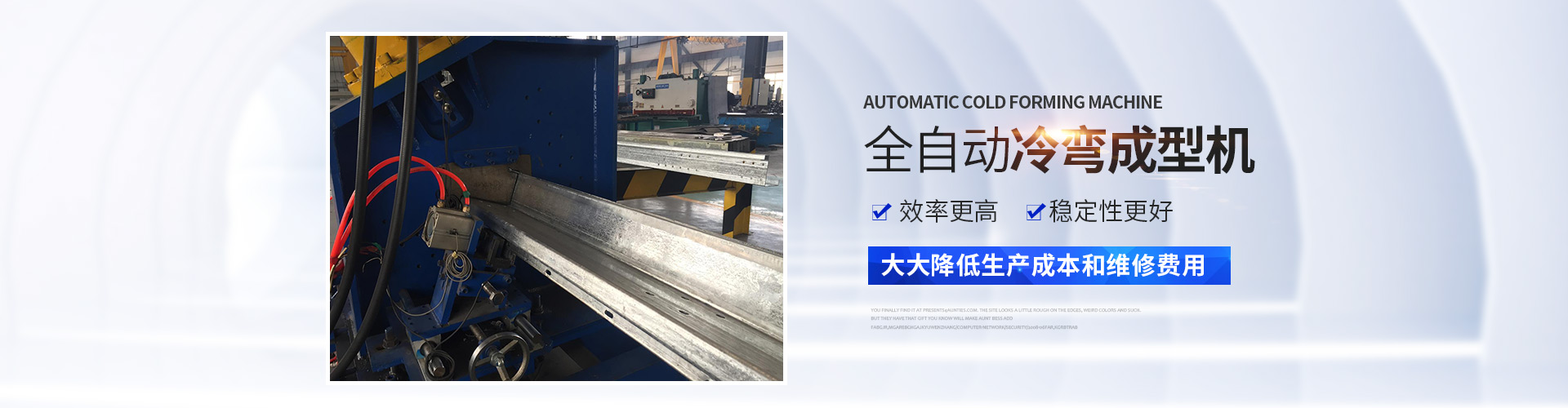

边梁冷弯成型设备参数

工艺流程:

上料—板料校平—伺服送料数控冲孔—冷弯成型—型材校直—测孔定尺—液压自动切断—卸料

性能特点:

1.冷弯成型道次布局及设备结构设计科学合理,对带钢软硬程度适应范围广,轧制过程中不会产生波纹、撕裂现象;

2.通过伺服控制,结合高速液压冲孔机构,采用带钢冲孔,然后再连续冷弯轧制,能够按照要求冲孔及冲口,并保证尺寸度;且生产率高;

3.布局合理,冲孔前后缓冲装置,伺服送料冲孔、冷弯成型、液压切断不停机,提高生产效率;

4.操作人员需一人;

技术参数:

1.生产线长度50米,整机功率约80KW;

2.生产速度0—4米/min可调;

3.数控冲油缸频率每秒钟一次以上;

4.数控冲运动型CAD柔性控制,可电脑编程,在线输入、加工,有记忆功能;

5.主机PLC控制,彩色触摸屏可直接输入数据,控制主机动作;

6.通过调整可满足不同规格边梁型材轧制,实现一机多用 ;

Parameters of cold forming equipment for edge beam

Process:

Feeding-Plate leveling-Servo feeding CNC punching-Cold forming-profile straightening-Hole Calibration-hydraulic autotic cutting-unloading

Perfornce features:

1. The cold forming pass layout and equipment structure design are scientific and reasonable, which can adapt to wide range of soft and hard degree of strip, and will not produce ripple and tear phenomenon in rolling process.

2. Through servo control, combined with high speed hydraulic punching mechani, using strip steel punching, then continuous cold bending rolling, punching and punching according to requirements, and ensuring dimensional accuracy, and high productivity;

3. the layout is reasonable, before and after punching, cushion, servo feeding, punching, cold bending, hydraulic cutting and no stopping, improve production efficiency;

4. The operator needs one person;

Technical parameters:

1. The length of the production line is 50m, the power of the whole chine is about 80kW;

2. The production speed is adjustable from 0 to 4 m / min;

3. CNC cylinder frequency per second or more;

4. CNC impact movement CAD flexible control, computer programming, on-line input, processing, memory function;

5. Host PLC control, color touch screen can directly input data, control host action;

6. The multi-purpose of a chine can be realized by adjusting the profile of side beam with different specifications.

边梁冷弯成型设备设计原则:

此设计本着使用可靠,便于维护,零部件限度的标准化、通用化、使用寿命正常化,投资省,关键部位高标准,辅助部位保使用,轧辊易互换、基准统一化的原则。

边梁冷弯成型设备设计依据:

根据需方提供要求,整机自动流水作业,产品样件满足提供图纸要求,参照冷弯型钢的标准GB6723—86《通用冷开口型钢尺寸外形,变量及允许偏差》、GB6724—86《冷弯波型钢板》、GB6726—86《货运汽车冷弯型钢尺寸、外形、变量及允许偏差》。

Design principle of side beam cold forming equipment:

This design is based on the principles of reliable use, easy intenance, ximum standardization, generalization of parts, norlization of service life, low investment, high standard of key parts, intenance of auxiliary parts, easy exchange of rolls, and standardization of reference.

The design basis of the side beam cold bending forming equipment:

According to the requirements of the dend side, the whole chine will flow autotically, and the product samples will meet the requirements of the drawings, and refer to the national standard GB6723-86 of the national standard for cold-formed section steel (GB6723-86). Variable and allowable deviation > GB6724-86 < Cold-formed Steel Plate > GB6726-86 < size, shape, variable and allowable deviation of Cold formed Steel for Freight cars.

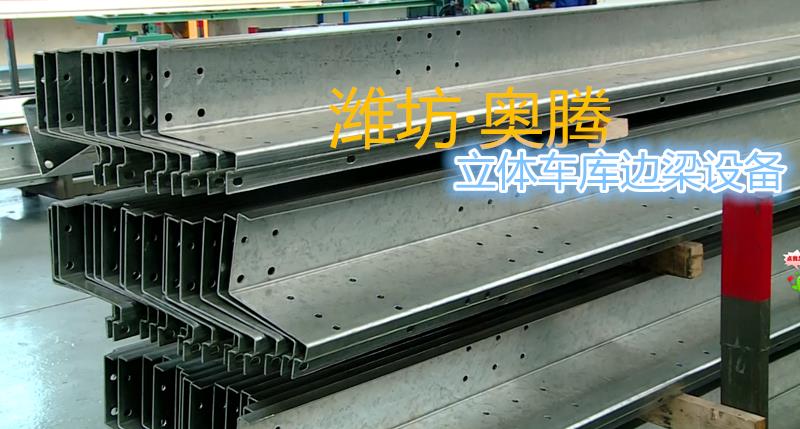

山东立体车库边梁成型设备-全自动车库边梁一次成型设备-|潍坊奥腾冷弯机械有限公司|-全自动车库边梁成型生产线-山东立体车库边梁生产设备

http://aotengjixie.cn.b2b168.com