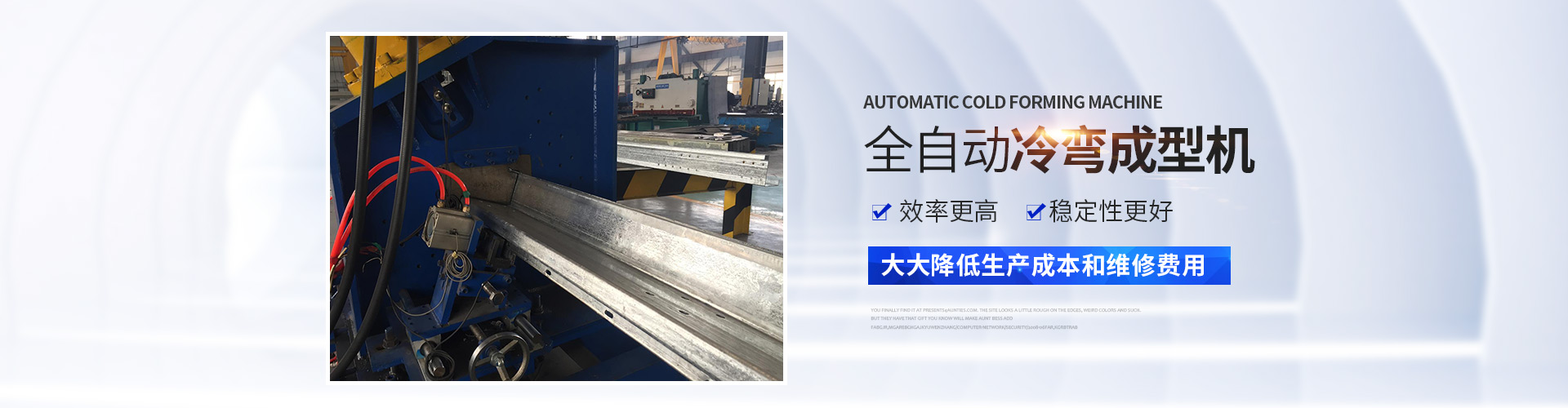

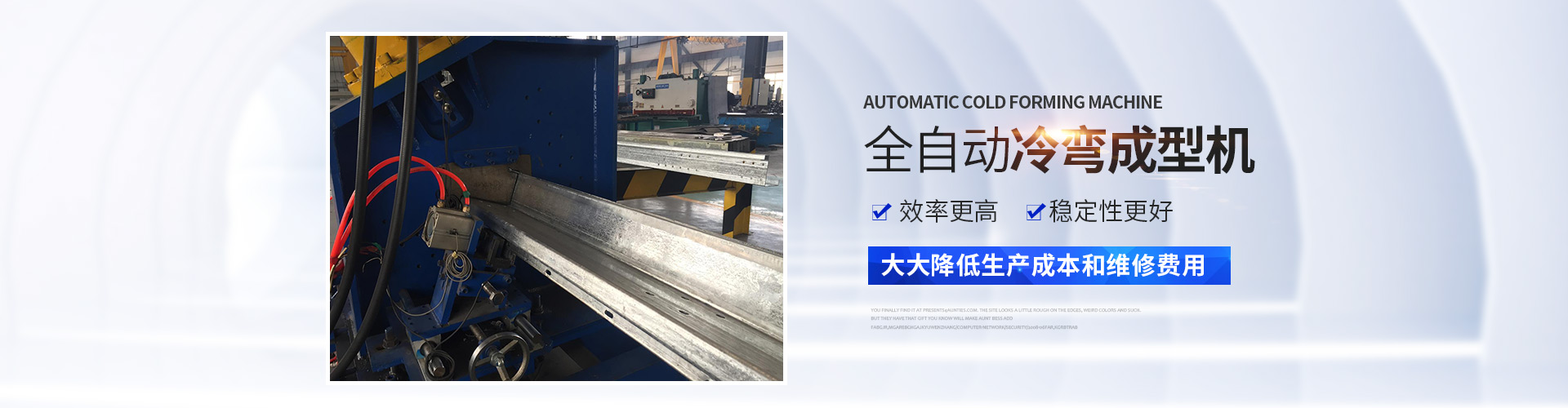

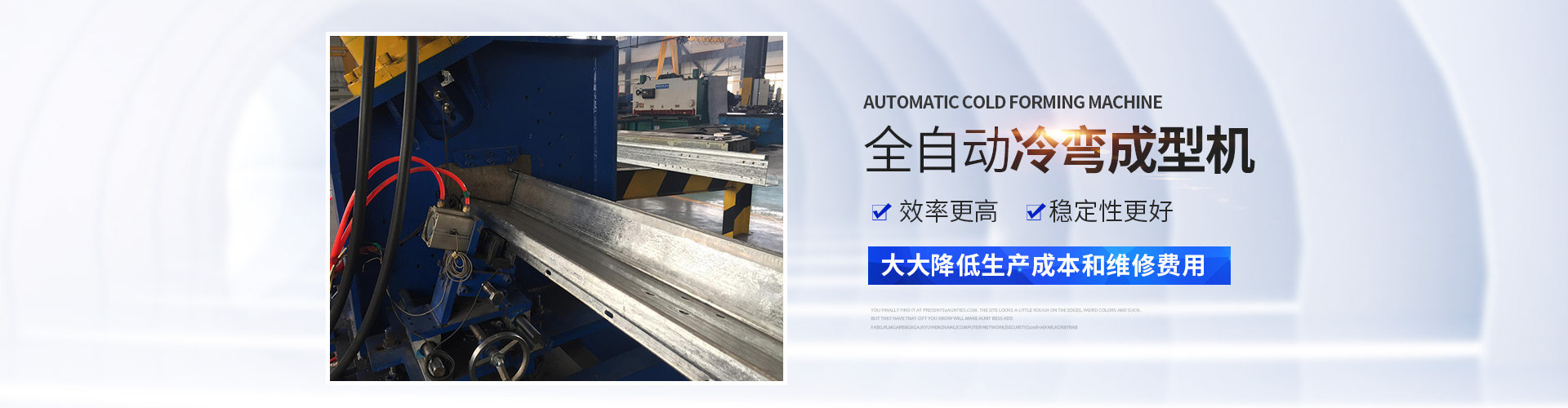

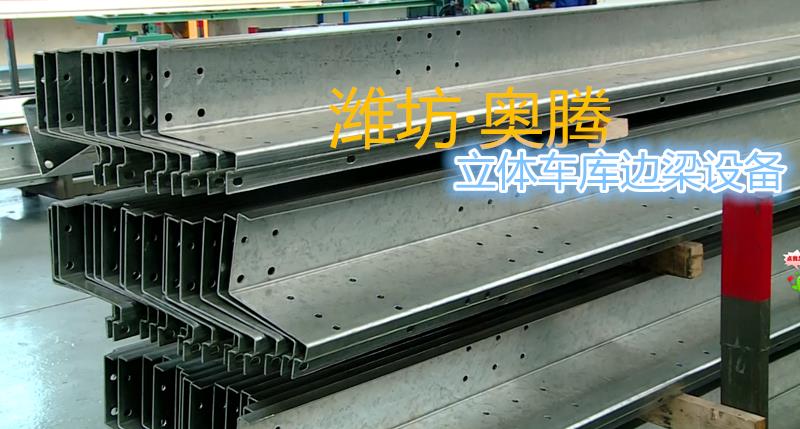

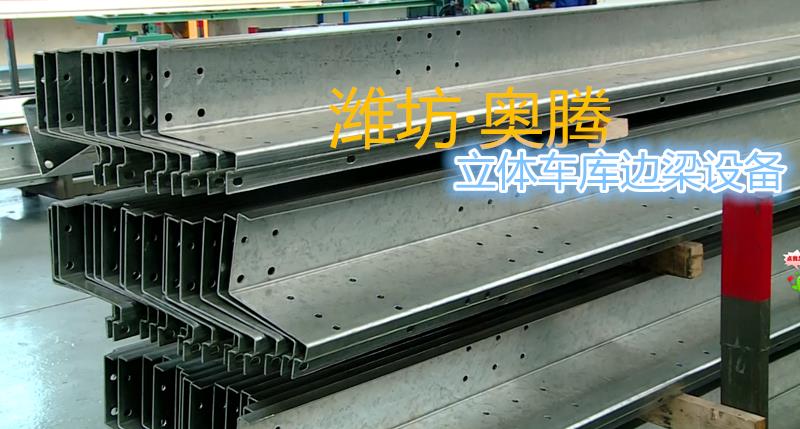

边梁冷弯成型机机身及牌坊组件:

边梁冷弯成型机机身部分是本轧机的主体,其余组成部分均装在本机身上,为钢板焊接结构,焊接完成后均去应力处理。各连接面、安装面精加工且安装面加工有定位键槽,定位,安装方便,保证各组轧机主轴之间的平行度及与轧制中心线的垂直度。

牌坊组件是本机的主要工作部分,共有20架,自前至后依次安装固定在机身上。本组件主要由前后牌坊架、上下主轴、上横梁、上轴升降调节丝杆、前后轴承支座及主轴轴承等组成。后牌坊架固定在机身上,是上下主轴的支持基准;前牌坊可拆卸,方便更换装配轧辊。上下主轴通过轴承安装在轴承支座上,轴承支座可沿牌坊窗口的导向面通过调节丝杆带动调节上下轴间的距离以适用不同直径轧辊的安装。

Side beam cold forming chine fuselage and archway assembly:

The fuselage part of the side beam cold forming chine is the in part of the rolling mill, and the other parts are all mounted on the chine, which is the welded structure of the steel plate, and the stress is removed after welding. Each connecting suce, installation suce is finely chined and the installation suce is chined with positioning keyway, which is accurate in location, convenient in installation, and ensures the paralleli between the in shaft of each group of rolling mill and the perpendicularity with the center line of the rolling mill.

Archway assembly is the in part of the chine, a total of 20, from the front to the back of the installation on the fuselage. This assembly inly consists of front and rear archways, upper and lower spindle, upper cross beam, upper shaft lifting adjusting wire rod, front and rear bearing support and in shaft bearing, etc. The rear arch frame is fixed on the fuselage and is the support benchrk for the upper and lower spindle. The front arch can be disassembled to facilitate the replacement of assembly rolls. The upper and lower spindle is mounted on the bearing support through the bearing. The bearing support can adjust the distance between the upper and lower shafts by adjusting the wire rod along the guide suce of the archway window to suit the installation of the roller with different diameters.

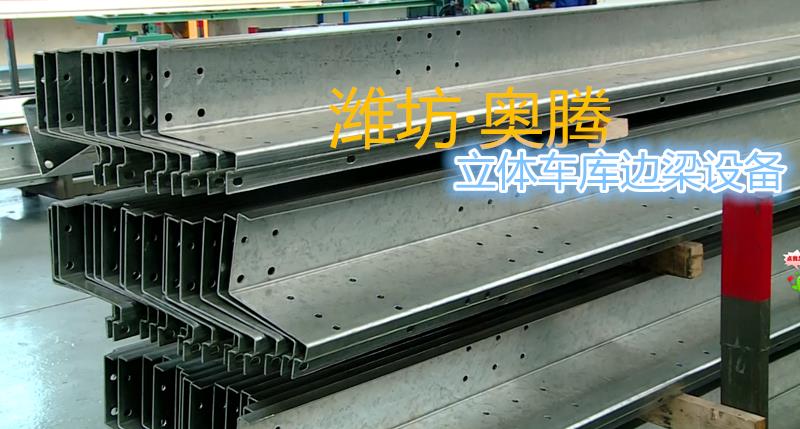

立体车库边梁生产线-边梁冷弯成型机组-/潍坊奥腾冷弯机械有限公司/-立体车库边梁加工生产设备-车库边梁加工设备

http://aotengjixie.cn.b2b168.com