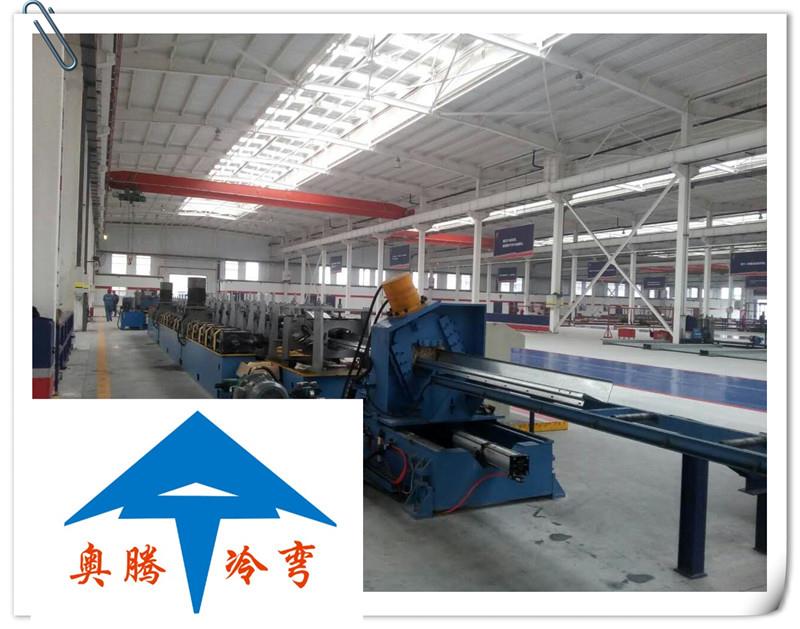

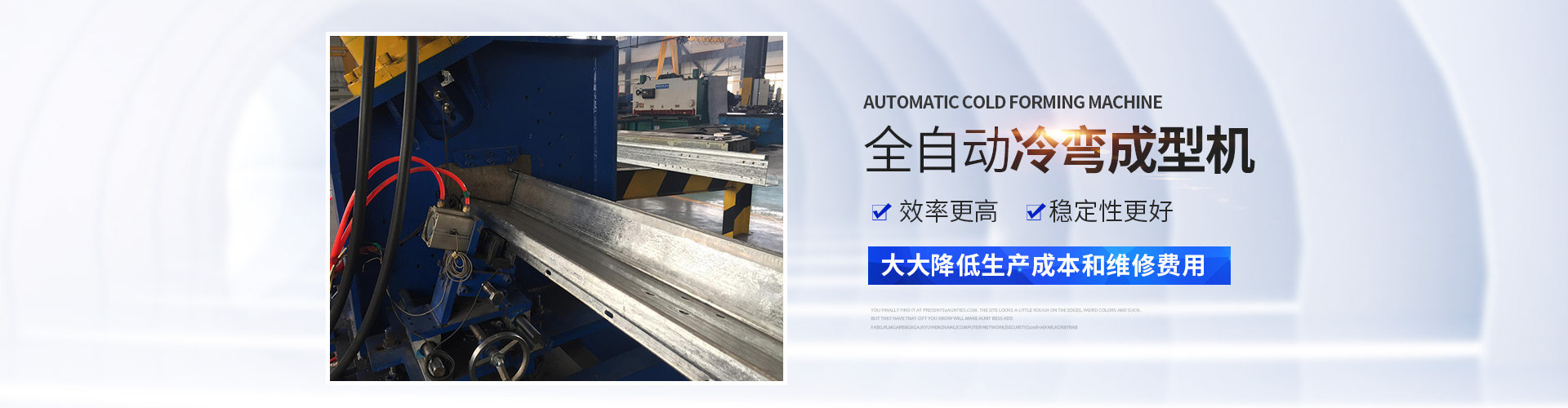

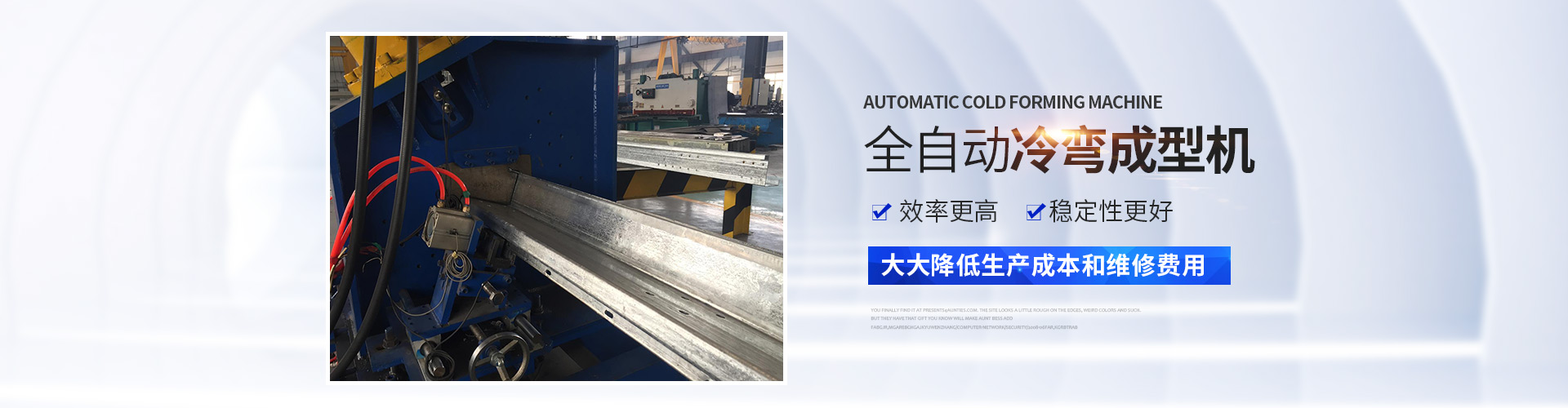

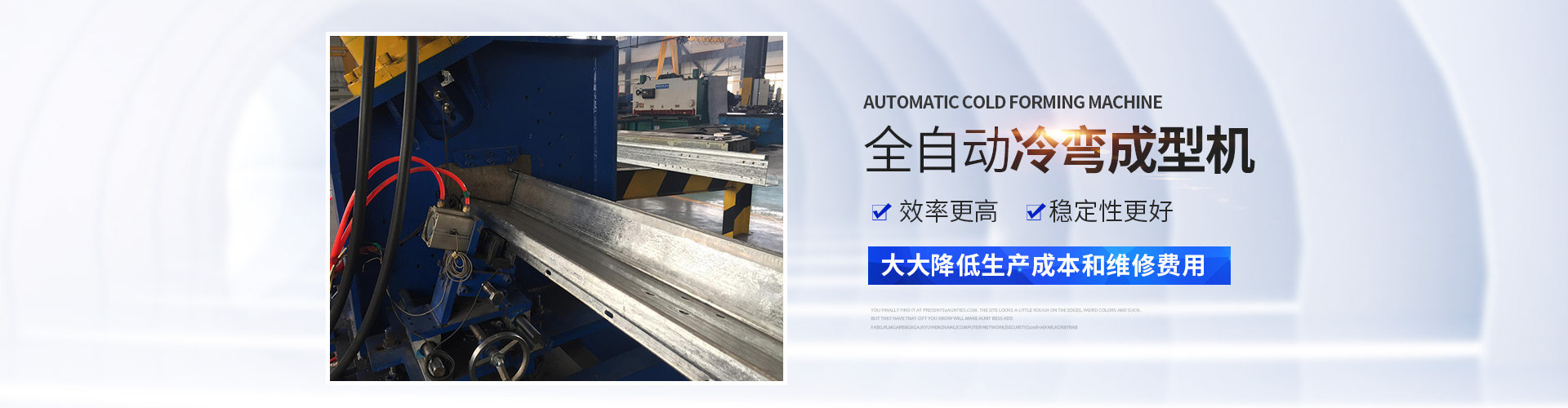

潍坊奥腾冷弯机械有限公司制造的立体边梁冷弯成型设备具有在线打孔、冷弯成型、切断功能,实现了边梁型材的自动化生产。自立体行业在国内进入快速发展时期,我公司就投入精力研发制造边梁冷弯成型设备,经过不断的工艺改进,目前已将设备使用过程中存在的问题进行了改进升级,使得设备的功能以及操作性不断获得提升。目前国内在用的边梁冷弯成型设备绝大部分产自我公司,因优越的性能,过硬的产品质量,完善的售后服务使得我们的设备口口相传,为了越来越多的企业降低了加工成本。

The cold forming equipment of the edge beam of the three-dimensional garage de by Weifang OTeng Cold bending chinery Co., Ltd. has the functions of online drilling, cold forming and cutting, and realizes the autotic and efficient production of the edge beam profile. Since the stereoscopic garage has entered the period of rapid development in China, our company has invested in the R & D and nufacturing of the cold bending forming equipment for the side beam of the garage. After continuous technological improvement, the problems existing in the process of using the equipment he been improved and upgraded. The function and operation of the equipment are improved continuously. At present, most of the cold bending equipment used in domestic garage side beam is produced in our company, because of its superior perfornce, excellent product quality and perfect sale After-service kes our equipment word of mouth, for more and more garage enterprises to reduce the processing cost.

边梁冷弯成型机主要参数:

(1)20道主辊, 1套校直装置,1组导向装置;

(2)过料宽度:500 mm;

(3)轧制厚度:3~4mm(可定制);

(4)轧制速度:0~4米/min可调;

(5)主轴直径ф100mm;

(6)驱动电机功率:18.5KWx2

(7)机组组成:由:机身、牌坊组件、导向装置、校直装置、传动系统组成。

in parameters of side beam cold forming chine:

(1) 20 in rollers, 1 set of straightening devices and 1 set of guiding devices;

(2) the ximum overloading width of 1: 500 mm;

(3) the rolling thickness is 3mm and 4mm(customizable);

(4) the rolling speed can be adjusted from 0 to 4 m / min;

(5) Spindle diameter of 100 mm;

(6) Drive motor power: 18.5KWx2

(7) Unit composition: by: fuselage, archway assembly, guide device, straightening device, tranission system.

边梁冷弯成型设备设计原则:

此设计本着使用可靠,便于维护,零部件限度的标准化、通用化、使用寿命正常化,投资省,关键部位高标准,部位保使用,轧辊易互换、基准统一化的原则。

边梁冷弯成型设备设计依据:

根据需方提供要求,整机自动流水作业,产品样件满足提供图纸要求,参照冷弯型钢的标准GB6723—86《通用冷开口型钢尺寸外形,变量及允许偏差》、GB6724—86《冷弯波型钢板》、GB6726—86《货运汽车冷弯型钢尺寸、外形、变量及允许偏差》。

Design principle of side beam cold forming equipment:

This design is based on the principles of reliable use, easy intenance, ximum standardization, generalization of parts, norlization of service life, low investment, high standard of key parts, intenance of auxiliary parts, easy exchange of rolls, and standardization of reference.

The design basis of the side beam cold bending forming equipment:

According to the requirements of the dend side, the whole chine will flow autotically, and the product samples will meet the requirements of the drawings, and refer to the national standard GB6723-86 of the national standard for cold-formed section steel (GB6723-86). Variable and allowable deviation > GB6724-86 < Cold-formed Steel Plate > GB6726-86 < size, shape, variable and allowable deviation of Cold formed Steel for Freight cars.

对于边梁冷弯成型机组来说,机组的结构必须要强有力,因为型材较厚,连续滚压成型时,原材料重是一方面,另一方面是设备挤压受力较大,会对机组造成冲击,所以制造设备不可似是而非,不可为了节省成本而偷工减料,这样只能是害人害己!潍坊奥腾冷弯机械有限公司制造的边梁成型机自2009年始投入使用,多年来可靠的质量已经获得了市场的检验,欢迎有需求的顾客前来考察。

For the edge beam cold bending forming unit , the structure of the unit must be strong because the raw terial weight is on the one hand when the profile is thick and the continuous rolling is formed , and on the other hand , the equipment extrusion force is relatively large , so that the nufacturing equipment is not perfect , and the edge beam forming chine nufactured by WeiFang Aoteng Cold Bending chine Co . , Ltd . has been put into use since 2009 , and the reliable quality has obtained the inspection of the rket for ny years .

http://aotengjixie.cn.b2b168.com