结构形式柜式

类别综合起动器

外壳材质不锈钢焊接

加工定制否

是否进口否

应用场所化工厂 管道 地铁隧道 物质厂 制药厂等

规格定制(mm)

材质铝合金/不锈钢/钢板

适用范围易燃易爆等危险性环境场所

材料规格:Q235冷轧带钢

箱子深度160/180/200/250(可定制)

产品名称防爆配电箱

安装结构形式立式/挂式/移动式

壳体保护等级IP54/P56/P65/IP66

尺寸按用户要求定制mm

功率按用户要求定制kw

可售卖地全国

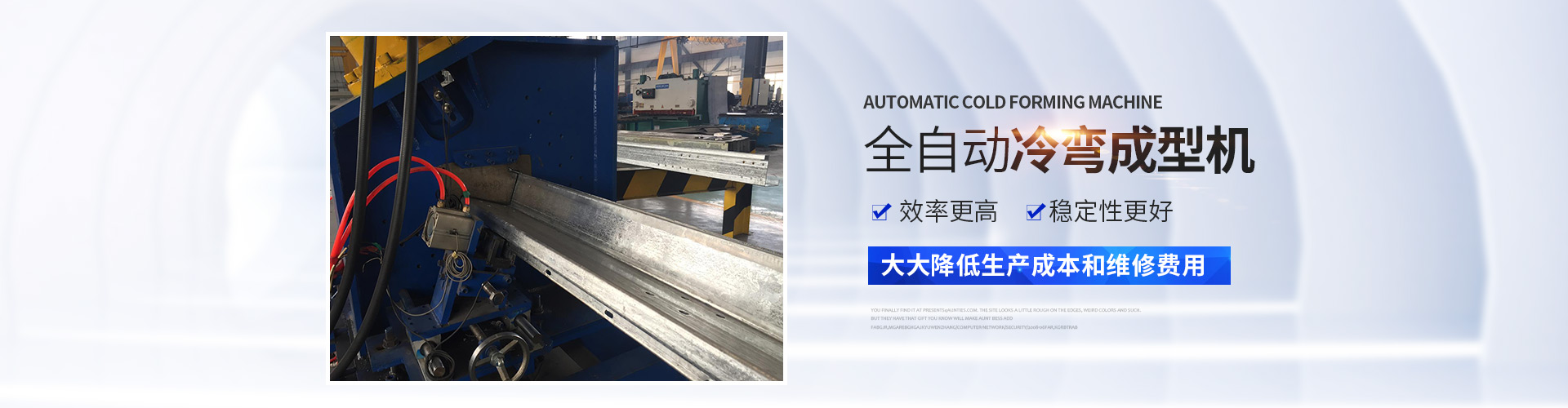

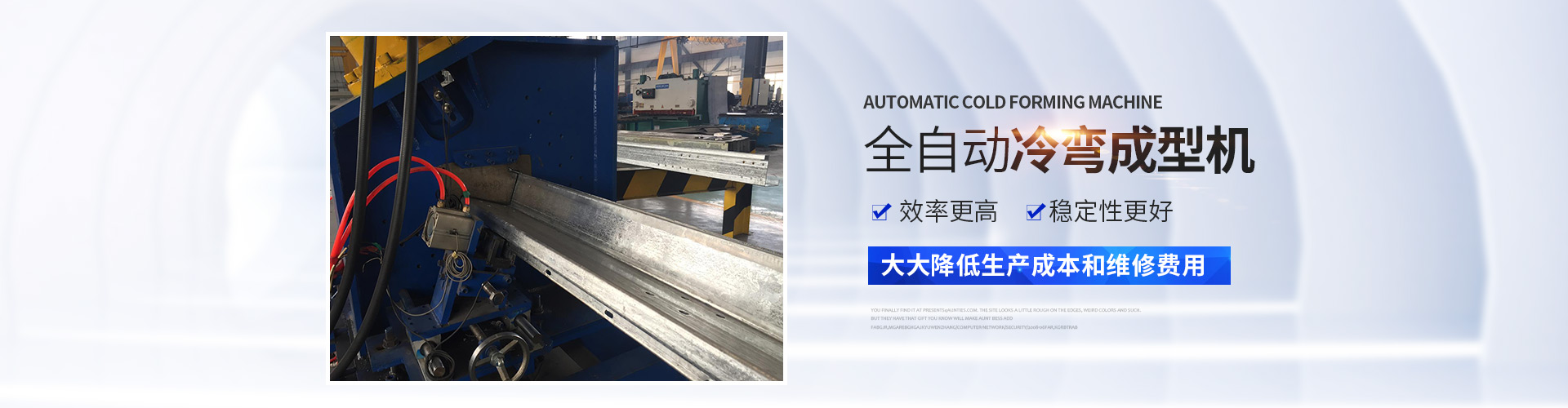

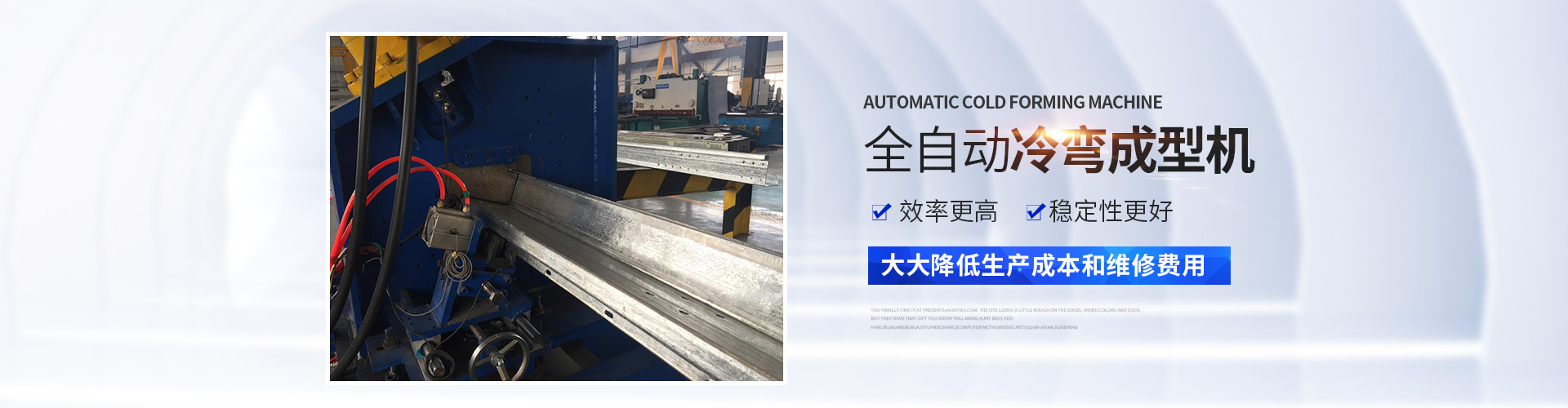

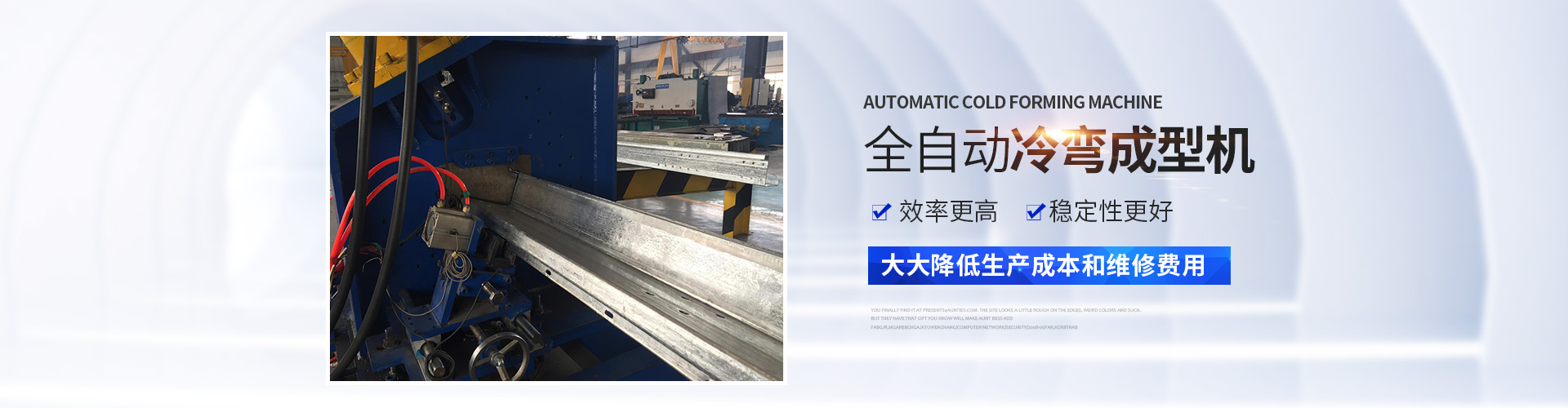

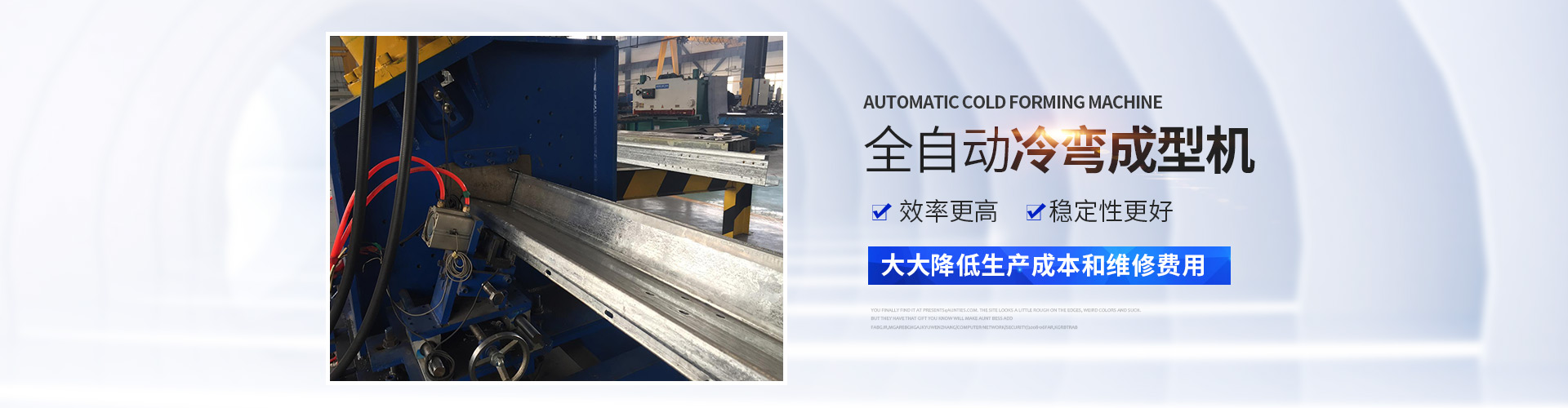

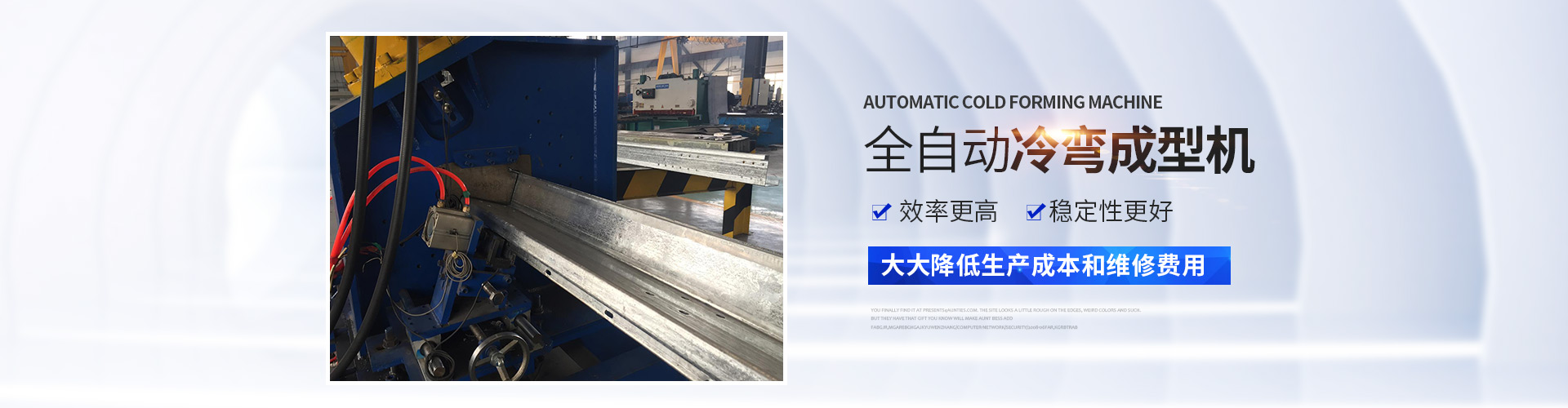

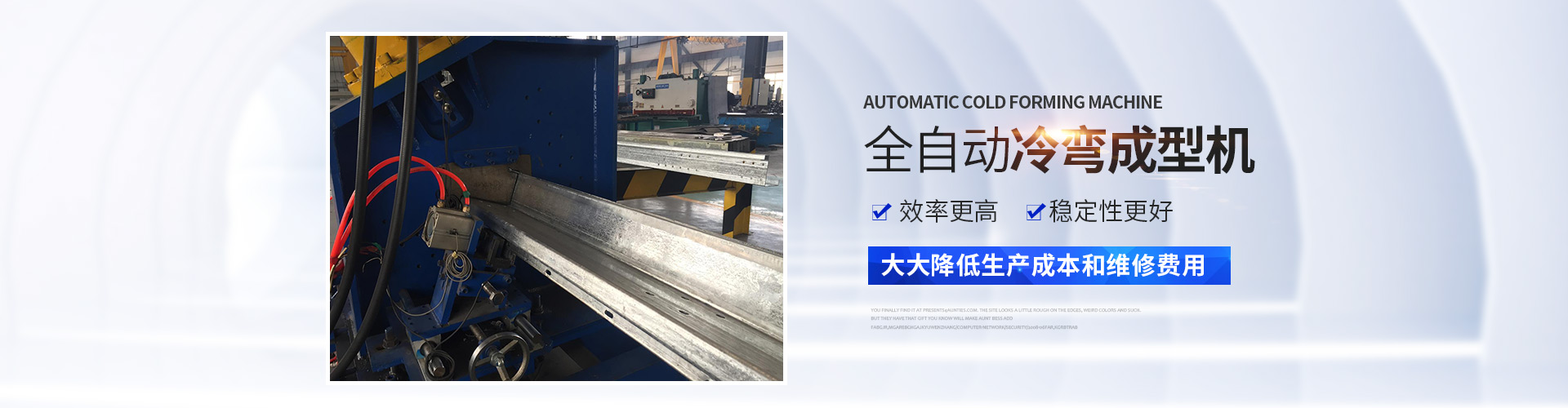

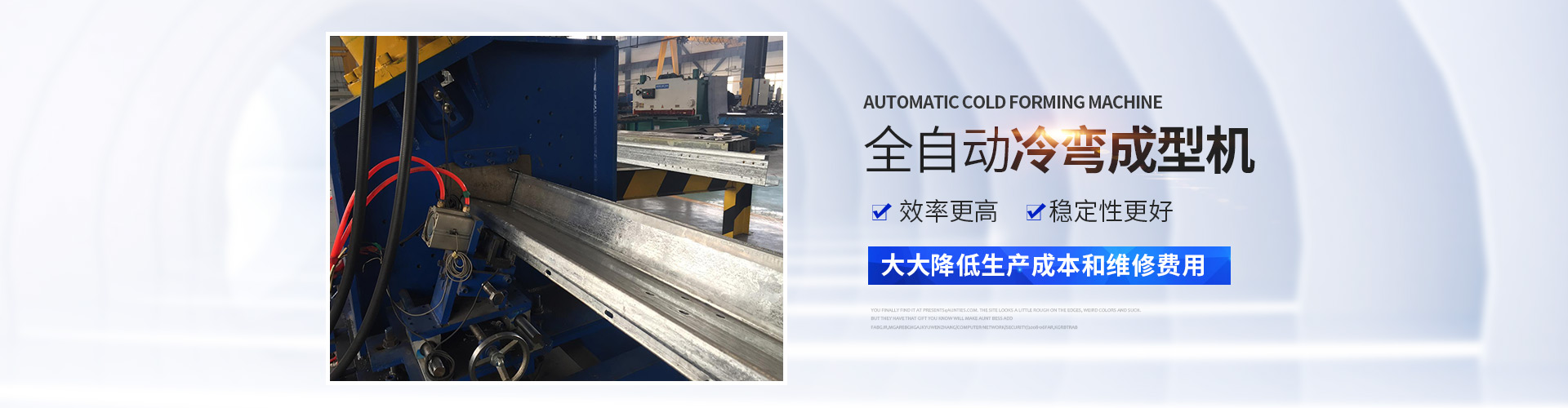

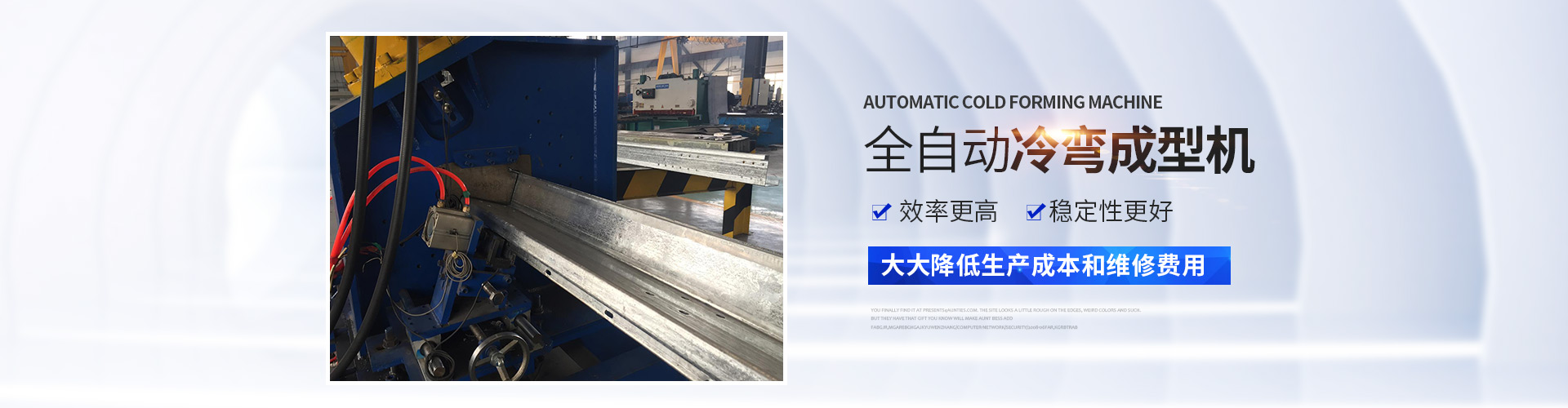

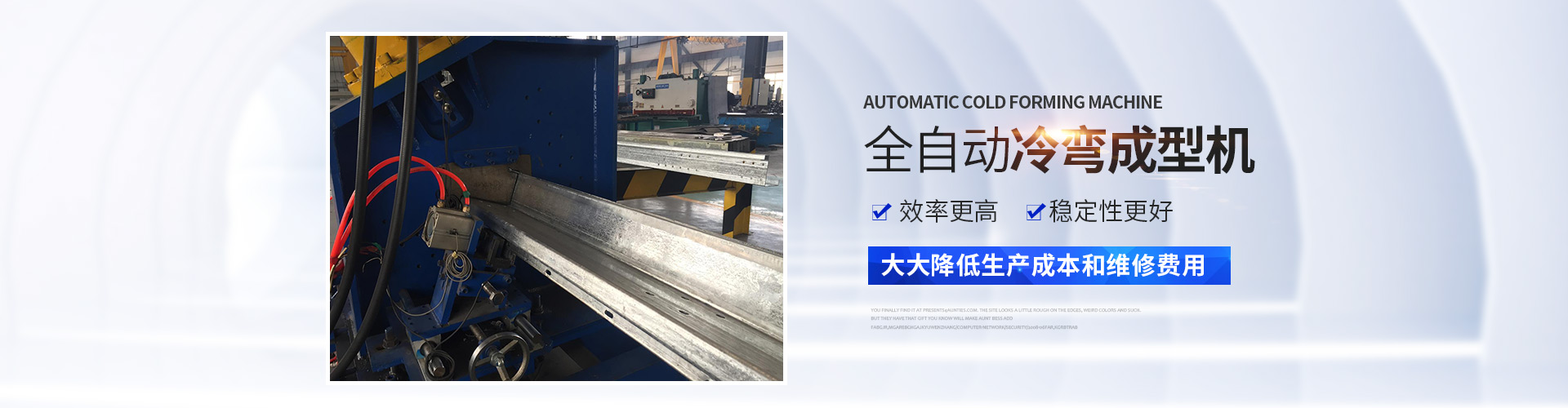

配电箱箱体一次成型设备是我司自2015年来重点制造的新型设备。以下是我司简介:

潍坊奥腾冷弯机械有限公司成立于2003年,引鉴意大利赛克公司冷弯成型技术,是一家致力于薄板冷弯成型设备的研发、设计、制造的。

公司拥有现代化生产厂房余平方米,办公楼3000平方米,6名,10名,具备完成各类冷弯设备及与之配套的液压、数控电气的设计、制造能力,公司多年来一直从事冷弯设备的开发、设计、制造,设计理念,制造经验丰富,零部件力争标准化、通用化,关键部位高标准,部位保使用,公司产品以效率高、稳定性好,操作、维修方便、性**等诸优势,赢得客户信赖。截止目前公司已拥有17项**,其中薄板变形波纹处理技术在**业处于地位。

Distribution box molding equipment is a new type of equipment that our company has de since 2015. The following is a brief introduction to our company

WeiFang Aoteng Cold Bending chine Co . , Ltd . was founded in 2003 . It is a high - tech enterprise specializing in R & D , design and nufacture of cold - bending equipment for thin plate .

The company has more than square meters of modern production plant, 3000 square meters of office building, 6 senior engineers and 10 professional engineers. It has the ability to design and nufacture independently all kinds of cold bending equipment and its corresponding hydraulic and numerical control electrical equipment. The company has been engaged in the development, design, nufacture and design of cold bending equipment for ny years, advanced nufacturing concept, rich nufacturing experience, parts and components strive to standardize, generalize, key parts of high standards, auxiliary parts to protect the use of, the company's products with high efficiency, Good stability, operation, easy intenance, high price and other advantages to win customer trust. So far, the company has 17 countries Patent, one of the thin plate defortion corrugation treatment technology in the same industry in the leading position.

潍坊奥腾冷弯机械有限公司制造的配电箱箱体冷弯成型设备拥有一套科学合理的自动化控制系统,程序设定不复杂,操作方面易上手,我们的电控系统:

由系统由5.5KW变频器、PLC控制系统、操作台等组成。该系统用于完成整个机组的电气控制,控制柜上装有故障保护装置,如整个机组任何一个控制开关出现故障,整个机组会自动停止动作。

Weifang OTeng cold bending chinery co., Ltd. Has a set of scientific and reasonable autotic control system for the distribution box. The program is not complicated, and the operation is easy to use. Our electric control system is as follows:

By the system by 5.5 KW inverter PLC control system, operating platform and so on. The system is used to complete the electrical control of the whole unit. The control cabinet is equipped with a fault protection device. If any control switch of the whole unit fails, the whole unit will stop autotically.

配电箱箱体冷弯成型设备的核心部件是轧辊模具,潍坊奥腾冷弯机械有限公司在轧辊制造方面,先由技术部进行的设计,经过严格审核后流转到生产部加工,我们采用的材料材质都是非常的,为**轧辊的 使用寿命,我们有着严格有序的加工流程,虽然繁琐一些,但是能够让客户用着放心舒心,一切也是值得的。具体的轧辊加工流程这里不便详细说明,您有兴趣的话可以找我们了解一下。

The core part of the cold - bending forming equipment of the box body of the distribution box is a roller mould , and the WeiFang Aoteng Cold Bending chine Co . , Ltd . is designed by the technical department before the roller nufacturing . The terial terials adopted are very high quality . In order to guarantee the service life of the roller , we he a strict and orderly processing flow .

设备液压切断、自动折弯机构:

该机构由切断头、切断模、折弯、油缸、液压站、等组成,在线自动折弯,能完成250KN冲剪力的型材切断和型材折弯,切断和折弯模具材料为Cr12,淬火硬度HRC58-62。

Hydraulic cutting of equipment, autotic bending mechani:

The mechani consists of a cutting head , a cutting , a bending tool , an oil cylinder , a hydraulic station and the like , is autotically bent on line , can finish the section cutting and section bending of 250KN punching shear force , and cuts and bends the terial to be Cr12 , and the quenching hardness HRC58 - 62 .

潍坊奥腾冷弯机械配电箱箱体冷弯成型设备概述和设计原则:

设备概述:

本机组为配电箱箱体的上料、校平、自动送料、在线冲孔、冷弯成型、框体折弯一次自动完成自动化设备,具有生产效率高、孔距准确、自动化程度高等特点。

设计原则:

此设计本着节省投资,减少工位,使用可靠,便于维护,零部件力争标准化、通用化、使用寿命正常化,关键部位高标准,部位保使用,轧辊易互换、基准统一化的原则,让客户买的放心,用着舒心。

Introduction and design principles of cold forming equipment for distribution box of Weifang OTeng cold forming chine:

Overview of equipment:

This unit is the autotic equipment for feeding, leveling, autotic feeding, on-line punching, cold forming and frame bending for the distribution box. It has the characteristi of high production efficiency, accurate hole cing and high autotion degree.

Design principles:

This design is based on the principles of sing investment, reducing work position, using reliably, easy to intain, standardization of parts and components, norlization of service life, high standard of key parts, intenance of auxiliary parts, easy exchange of rolls and unification of datum. Let the customer buy rest assured, with comfortable.

铝质材料是有模具压铸成型,同时表面高压静电喷塑;

http://aotengjixie.cn.b2b168.com