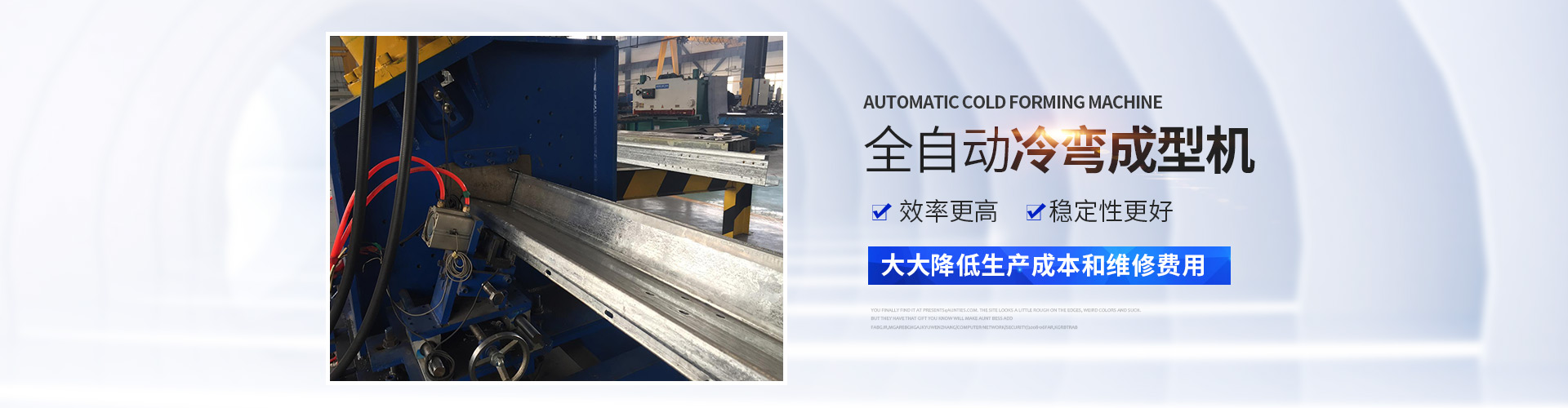

产品描述

基业箱箱体冷弯成型设备设计原则:

此设计本着使用可靠,便于维护,零部件限度的标准化、通用化、使用寿命正常化,投资省,关键部位高标准,辅助部位保使用,轧辊易互换、基准统一化的原则。

基业箱箱体冷弯成型设备设计依据:

根据需方提供要求,整机自动流水作业,产品样件满足提供图纸要求,参照冷弯型钢的国家标准GB6723—86《通用冷开口型钢尺寸外形,变量及允许偏差》、GB6724—86《货运汽车冷弯型钢尺寸、外形、变量及允许偏差》。

Design principles of cold forming equipment for base box:

This design is based on the principles of reliable use, easy maintenance, maximum standardization, generalization of parts, normalization of service life, low investment, high standard of key parts, maintenance of auxiliary parts, easy exchange of rolls, and standardization of reference.

Design basis of cold forming equipment for base box:

According to the requirements of the demand side, the whole machine will flow automatically, and the product samples will meet the requirements of the drawings, and refer to the national standard GB6723-86 of the national standard for cold-formed section steel (GB6723-86). Variables and allowable deviations. > GB6724-86 < size, shape, variable and allowable deviation of Cold formed Steel for Freight cars.

基业箱箱体冷弯成型机主机参数:

(1)18道主辊, 1套导向装置 (主机结构采用一侧固定,另一侧整体移动调整,更换箱体厚度尺寸时,只需人工按照尺寸刻度尺旋转手轮至合适位置即可);

(2)过料宽度:450 mm;

(3)常用轧制厚度:0.8-1.2mm(冷板/镀锌板)/0.8mm不锈钢

(4)冷弯轧制速度:2~3米/min;

(5)主轴直径ф55mm;

(6)主电机功率:5.5KW;

(7)冷弯成型机组成:该机是整个机组的主要工作部分。带钢经过连续的滚轧变形,即成为符合图纸要求的型材,本机由:机身、墙板组件、导向装置、校直装置、传动系统组成。

The main engine parameters of the base box cold forming machine:

(1) 18 main rollers and 1 guide device (the main structure is fixed on one side, the other side moves and adjusts as a whole, and when changing the thickness dimensions of the box, the handwheel can be manually rotated to the appropriate position according to the dimension scale);

( 2 ) Maximum material width : 450 mm ;

(3) commonly used rolled thickness: 0.8-1.2mm (cold plate / galvanized sheet) / 0.8mm stainless steel

(4) Cold bending rolling speed: 2 m / min;

(5) the spindle diameter 55mm;

(6) main motor power: 5.5KW;

(7) composition of cold forming machine: this machine is the main working part of the whole unit. After continuous rolling and deformation, the strip becomes the profile that meets the drawing requirements. The machine consists of: fuselage, wall panel assembly, guide device, straightening device, transmission system.

产品推荐