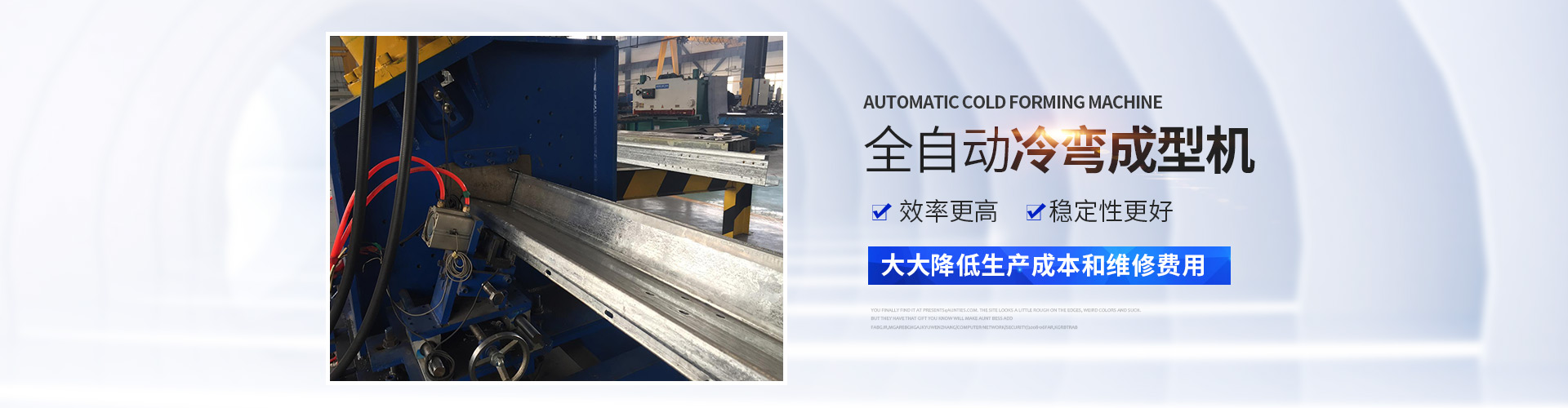

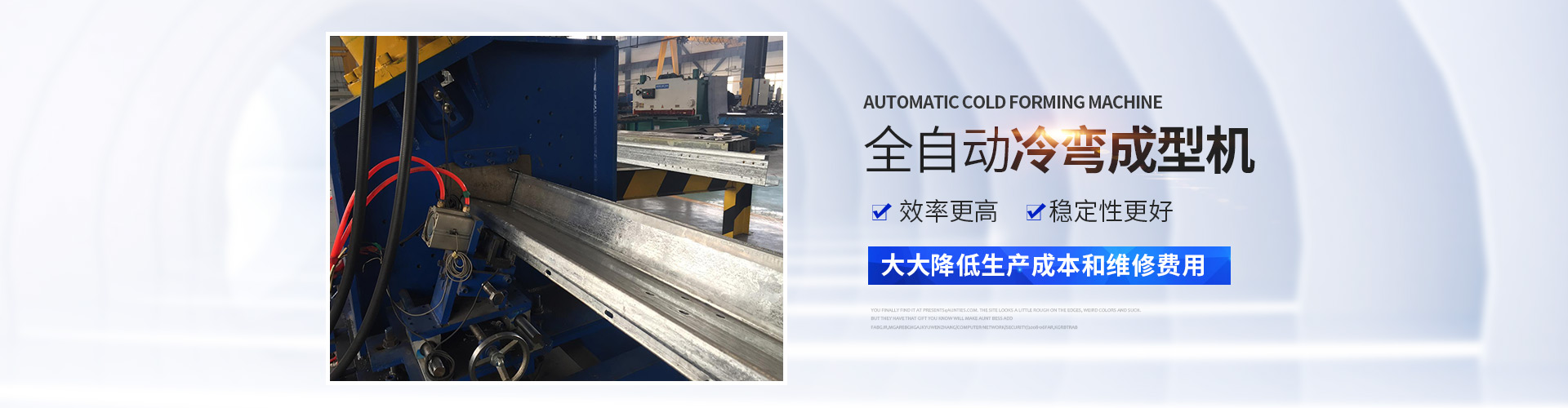

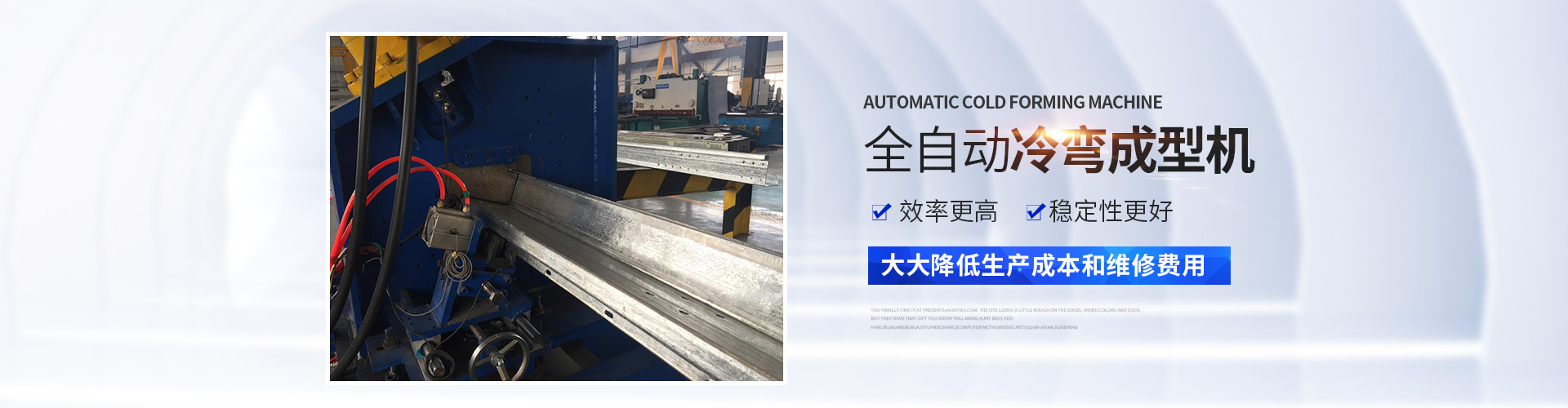

产品描述

优质的冷弯成型机具备那些特点呢:经久耐用的质量,简单的操作性,自动化程度高,完善的售后服务。潍坊奥腾冷弯机械有限公司拥有一支专业的研发团队和规模巨大的机加工机床群以及能打硬仗的钳工团体,能时刻保证产品从原材料加工到组装的精度。多年来,公司凭借先进的技术理念和优质的设备已经获得诸多老客户的再次订购。

High-quality cold-forming machine with those characteristics: durable quality, simple operation, high degree of automation, perfect after-sales service. Weifang Aoteng Cold bending Machinery Co., Ltd. has a professional research and development team and a large number of machined machine tools, as well as force-fighting machineries, which can guarantee the accuracy of products from raw materials processing to assembly at all times. Over the years, the company with advanced technology and quality equipment has been many old customers re-order.

基业箱箱体冷弯成型机主机参数:

(1)18道主辊, 1套导向装置 (主机结构采用一侧固定,另一侧整体移动调整,更换箱体厚度尺寸时,只需人工按照尺寸刻度尺旋转手轮至合适位置即可);

(2)过料宽度:450 mm;

(3)常用轧制厚度:0.8-1.2mm(冷板/镀锌板)/0.8mm不锈钢

(4)冷弯轧制速度:2~3米/min;

(5)主轴直径ф55mm;

(6)主电机功率:5.5KW;

(7)冷弯成型机组成:该机是整个机组的主要工作部分。带钢经过连续的滚轧变形,即成为符合图纸要求的型材,本机由:机身、墙板组件、导向装置、校直装置、传动系统组成。

The main engine parameters of the base box cold forming machine:

(1) 18 main rollers and 1 guide device (the main structure is fixed on one side, the other side moves and adjusts as a whole, and when changing the thickness dimensions of the box, the handwheel can be manually rotated to the appropriate position according to the dimension scale);

( 2 ) Maximum material width : 450 mm ;

(3) commonly used rolled thickness: 0.8-1.2mm (cold plate / galvanized sheet) / 0.8mm stainless steel

(4) Cold bending rolling speed: 2 m / min;

(5) the spindle diameter 55mm;

(6) main motor power: 5.5KW;

(7) composition of cold forming machine: this machine is the main working part of the whole unit. After continuous rolling and deformation, the strip becomes the profile that meets the drawing requirements. The machine consists of: fuselage, wall panel assembly, guide device, straightening device, transmission system.

产品推荐