产品描述

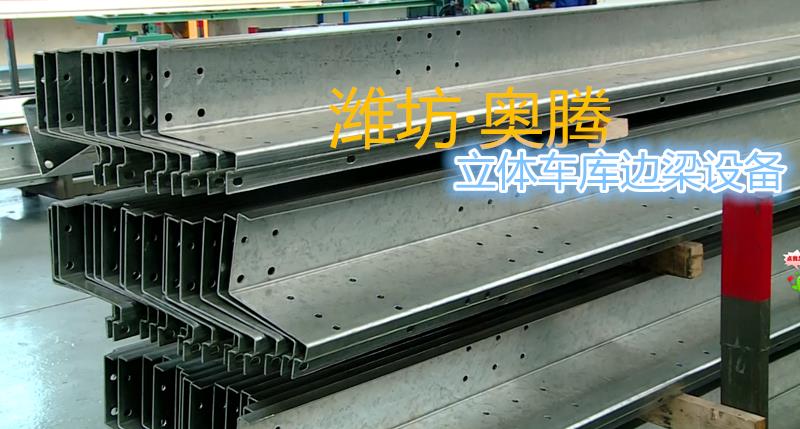

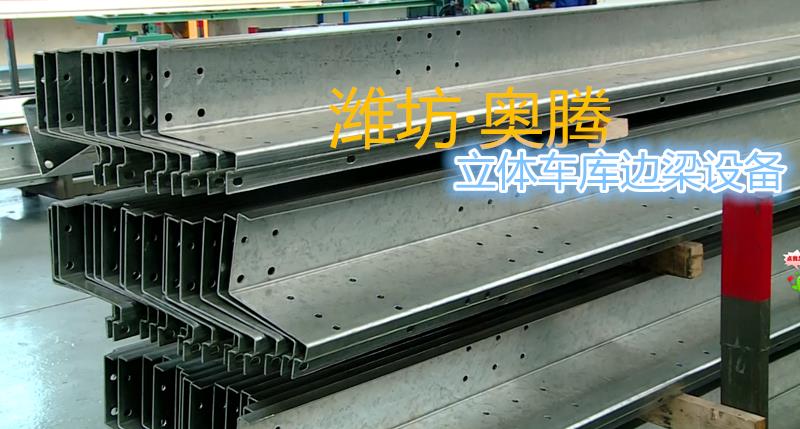

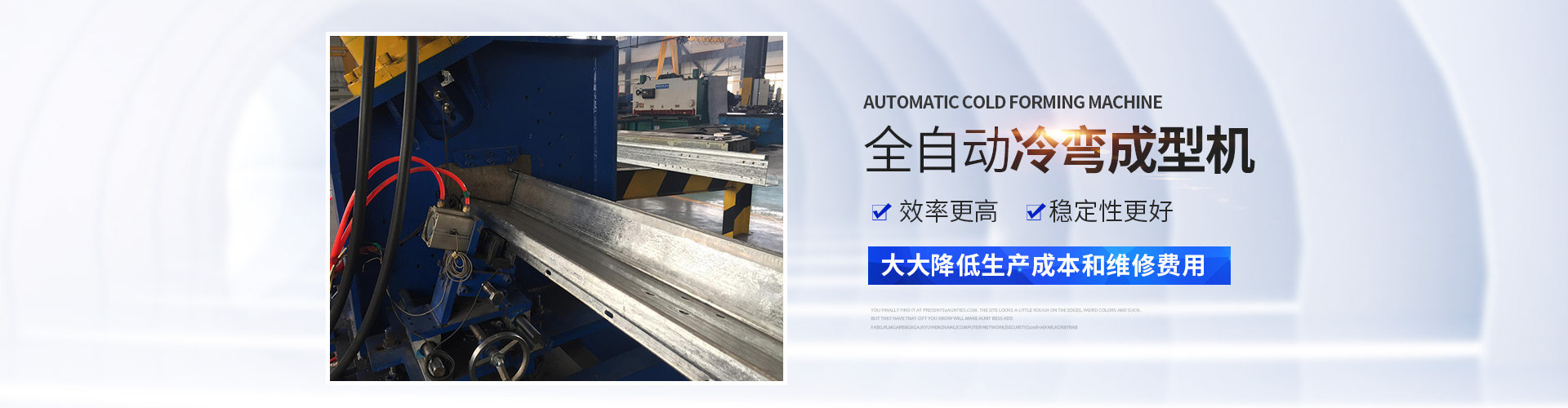

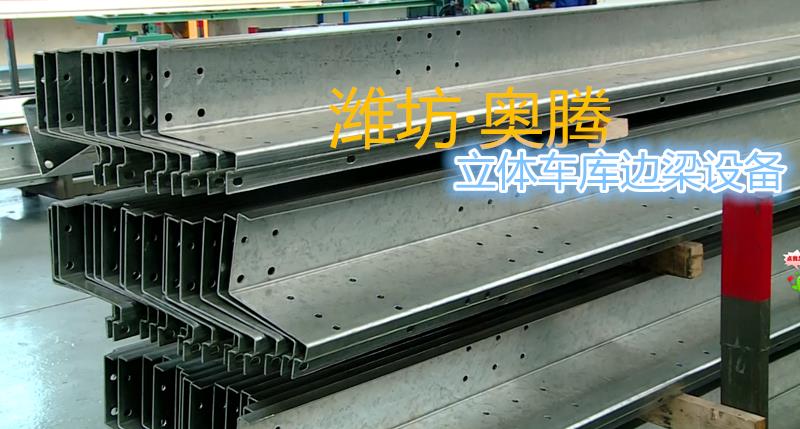

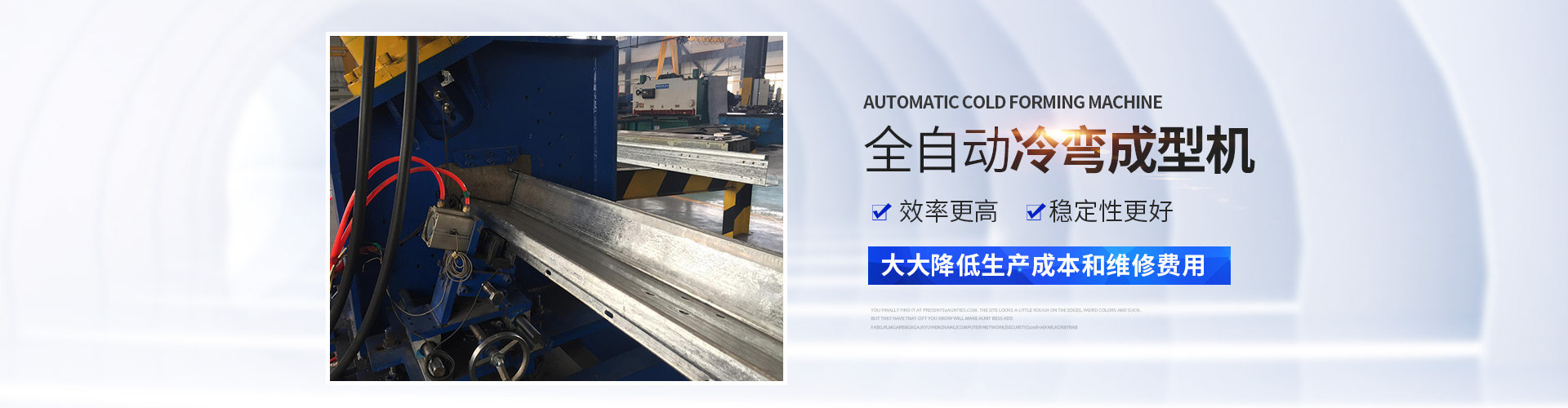

对于边梁冷弯成型机组来说,机组的结构必须要强有力,因为型材较厚,连续滚压成型时,原材料重是一方面,另一方面是设备挤压受力较大,会对机组造成冲击,所以制造设备不可似是而非,不可为了节省成本而偷工减料,这样只能是害人害己!潍坊奥腾冷弯机械有限公司制造的边梁成型机自2009年始投入使用,多年来可靠的质量已经获得了市场的检验,欢迎有需求的顾客前来咨询考察。

For the edge beam cold bending forming unit , the structure of the unit must be strong because the raw material weight is on the one hand when the profile is thick and the continuous rolling is formed , and on the other hand , the equipment extrusion force is relatively large , so that the manufacturing equipment is not perfect , and the edge beam forming machine manufactured by WeiFang Aoteng Cold Bending Machine Co . , Ltd . has been put into use since 2009 , and the reliable quality has obtained the inspection of the market for many years .

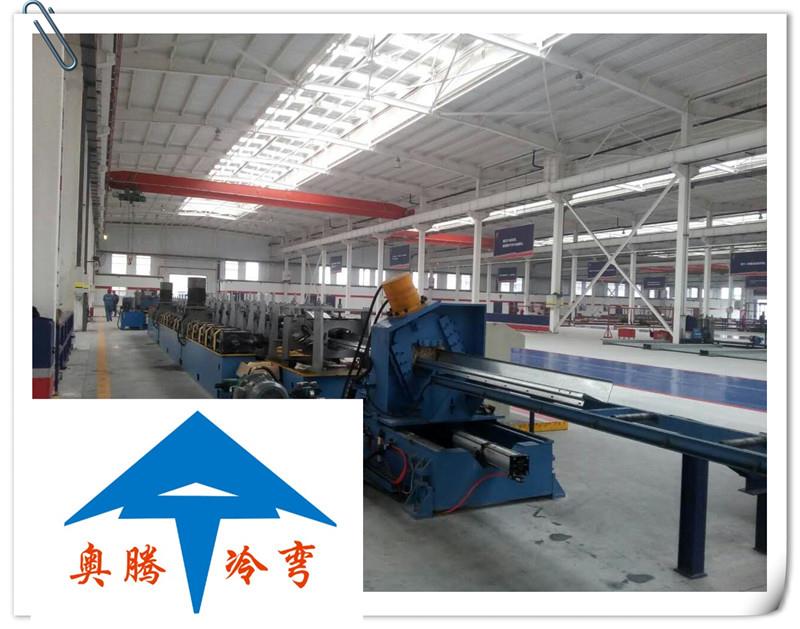

边梁冷弯成型设备制造质量控制情况

根据客户的要求,结合我公司生产部、质检科实际情况,对于设备的生产管理、质量控制情况,作出以下介绍:

1、生产管理:

由生产经理统筹规划,携2名生产计划调度员,合理安排各工序工作,保证加工车间、装配车间、质检科等各相关科室的工作顺利进行,已使所有工序零部件质量达到贵司产品质量要求。

2、质量控制:

⑴、设备外观:

①、设备整体表面整洁,油漆喷涂均匀完整,不流淌、无漏喷。轧辊表面、各导轨面、滑动面、滚动面及图纸有要求的位置不能喷漆。

②、未喷漆部位涂防锈油,轧辊模具等重要部件无磕碰划伤现象。

③、整机外漏部件除刃口外都作倒角、倒愣处理,去除尖角毛刺。

④、整机各焊接及装配固定组件保证其与相关部件的相对位置合理、准确。

⑵产品精度:

①、标准轧机的牌楼固定螺栓、横梁固定螺栓、轧辊轴锁紧螺母、基准锁紧螺母、轴承盖紧固螺栓等一定要紧固到位,轧辊轴与轧辊基准线要垂直,允差0.2~0.3/1000,不可累积。

②、安装校直架时要保证其中心与轧辊基准中心对正,保证左右调整间隙能满足型材弯曲的调整及多种规格型材的共用。

Manufacturing quality Control of Cold forming equipment for side Beam

According to the requirements of our customers, combined with the actual situation of our production department and quality inspection department, we will introduce the production management and quality control of the equipment.

1. Production management:

By the production manager overall planning, with 2 production planning dispatchers, reasonable arrangement of each process work, to ensure the processing workshop, assembly workshop, quality inspection department and other relevant departments work smoothly, Has made all the process parts quality up to your product quality requirements.

2. Quality control:

1. Device appearance:

1, the overall surface of the equipment clean, paint spray uniform integrity, no flow, no leakage spray. Roll surface, guide surface, slide surface, rolling surface and drawing must not be sprayed.

2. The anti rust oil is not painted at the painting part, and the important parts such as the roll die and so on are not scratched.

3. The external leakage parts of the whole machine are all chamfered except the cutting edge, so as to remove the burr of the sharp angle.

4. The relative position of welding and assembling fixed components is reasonable and accurate.

2 Product precision:

1. The fixed bolt of the standard rolling mill, the fixed bolt of the transverse beam, the lock nut of the roller shaft, the base lock nut, the fastening bolt of the bearing cover must be fastened in place, the roll shaft and the roller datum line should be vertical, and the allowance is 0.2~0.3/1000, not to be accumulated.

2. When installing the straightening frame, it is necessary to ensure the alignment between the center and the roller reference center, and to ensure that the left and right adjustment clearance can meet the profile bending adjustment and the sharing of many kinds of profiles.

产品推荐