加工定制是

执行标准国标

制作工艺定制

长度定制

加工服务定制样品

幕墙金属型铝型材的材质未按照设计要求选购

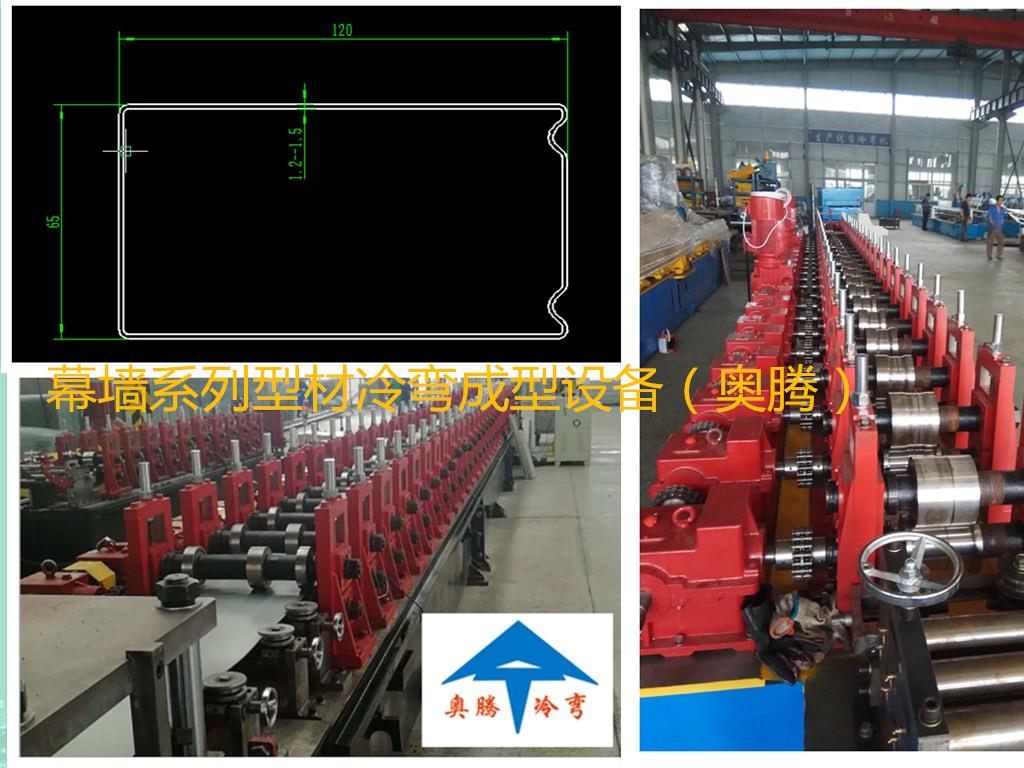

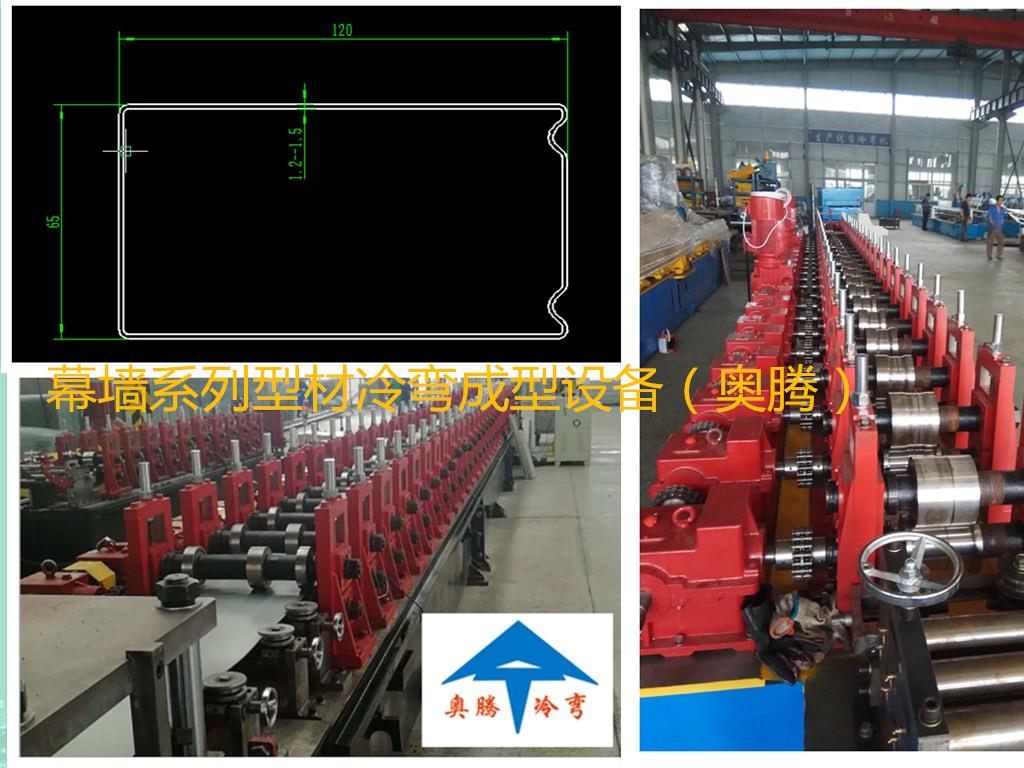

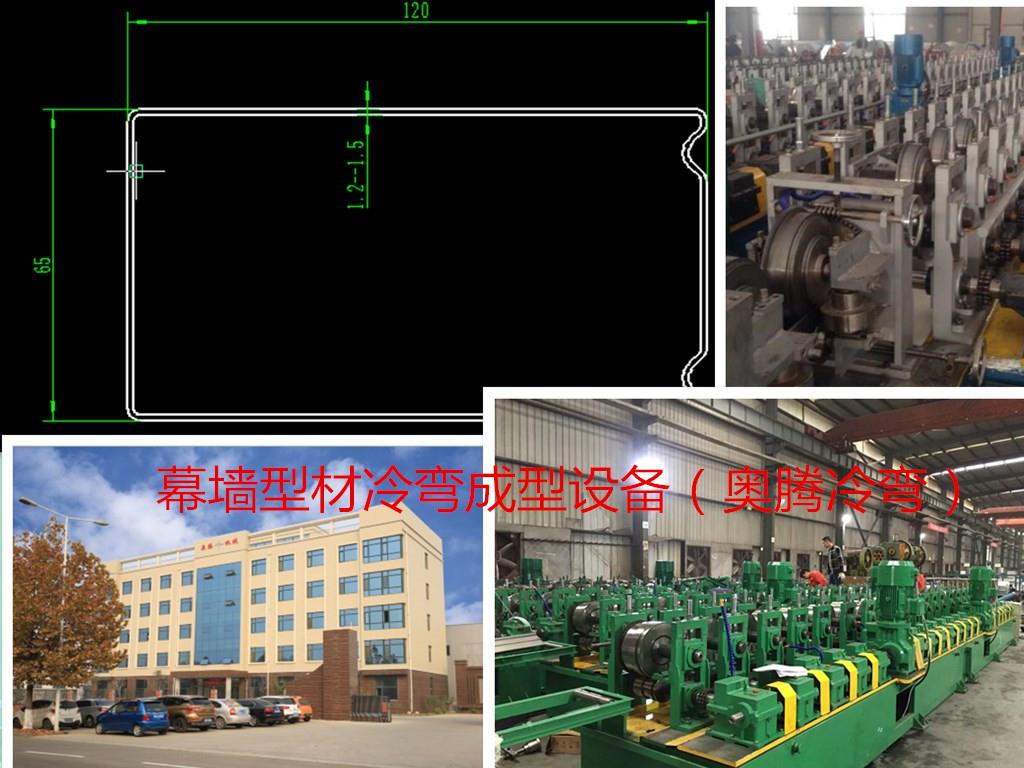

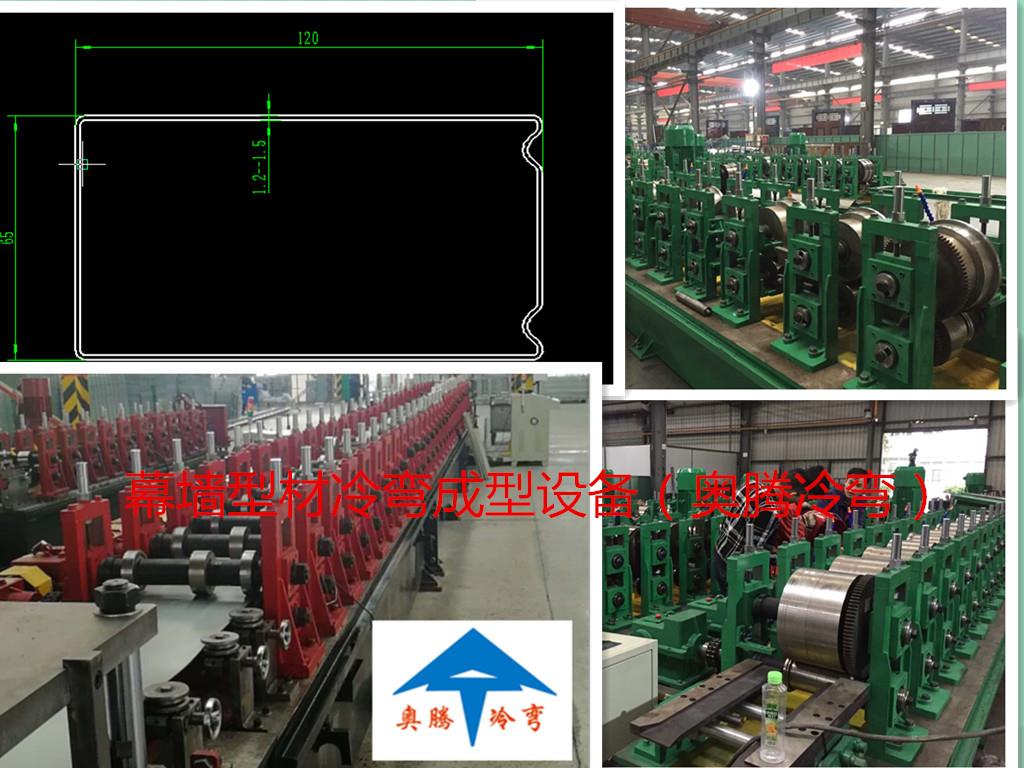

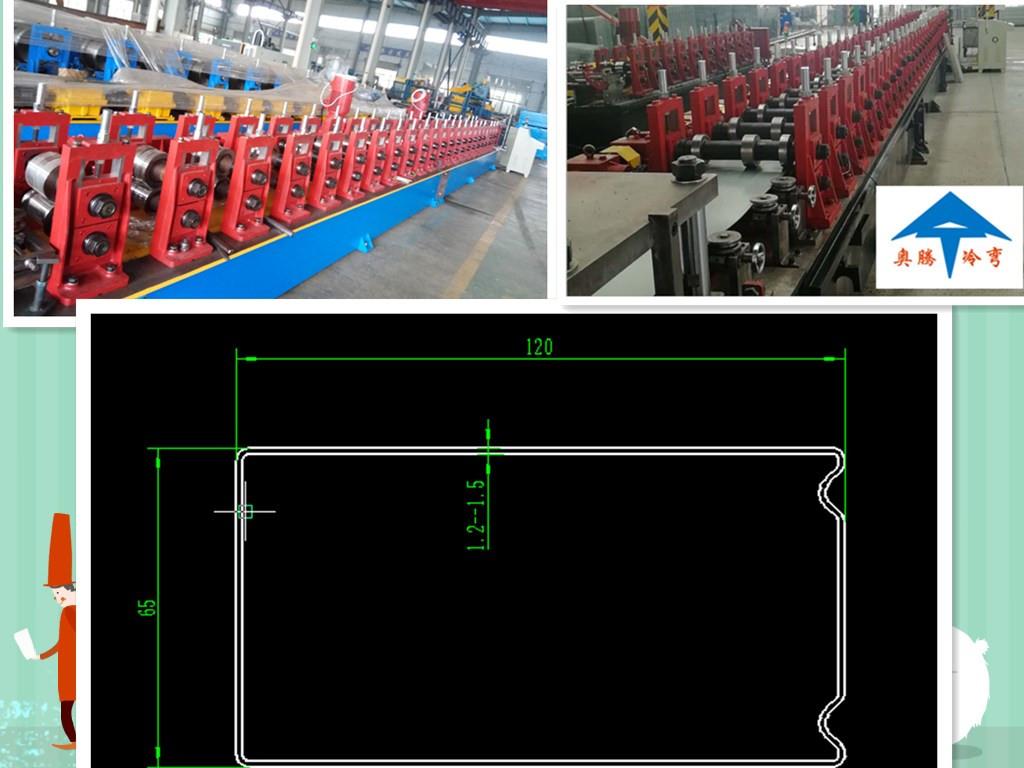

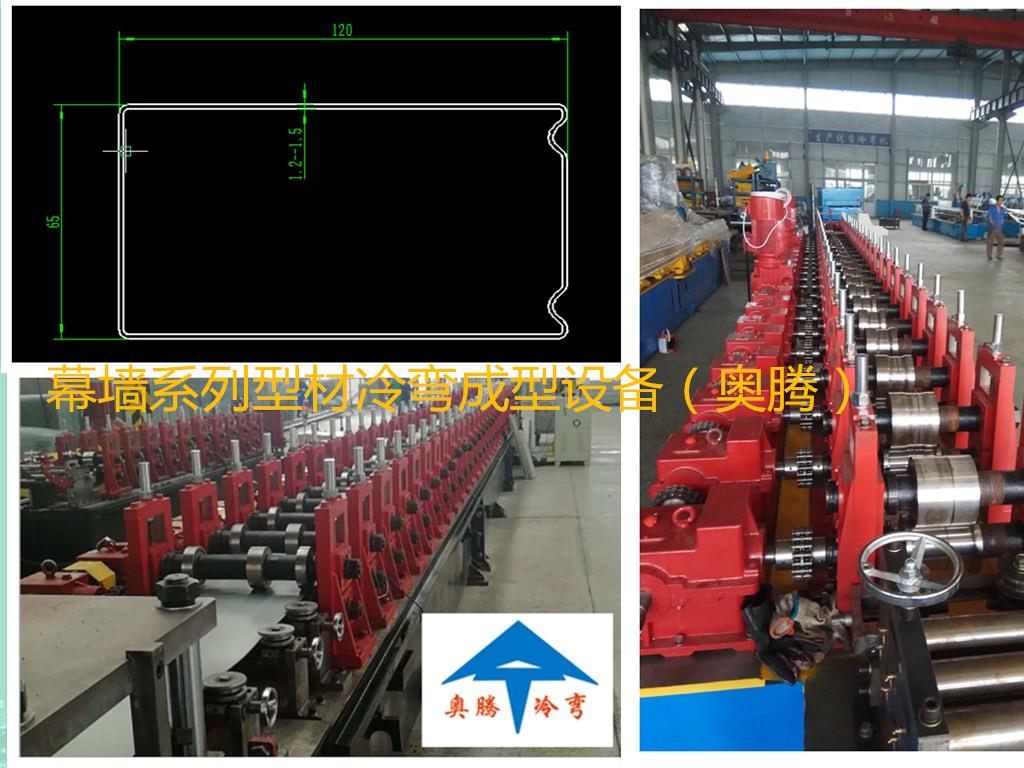

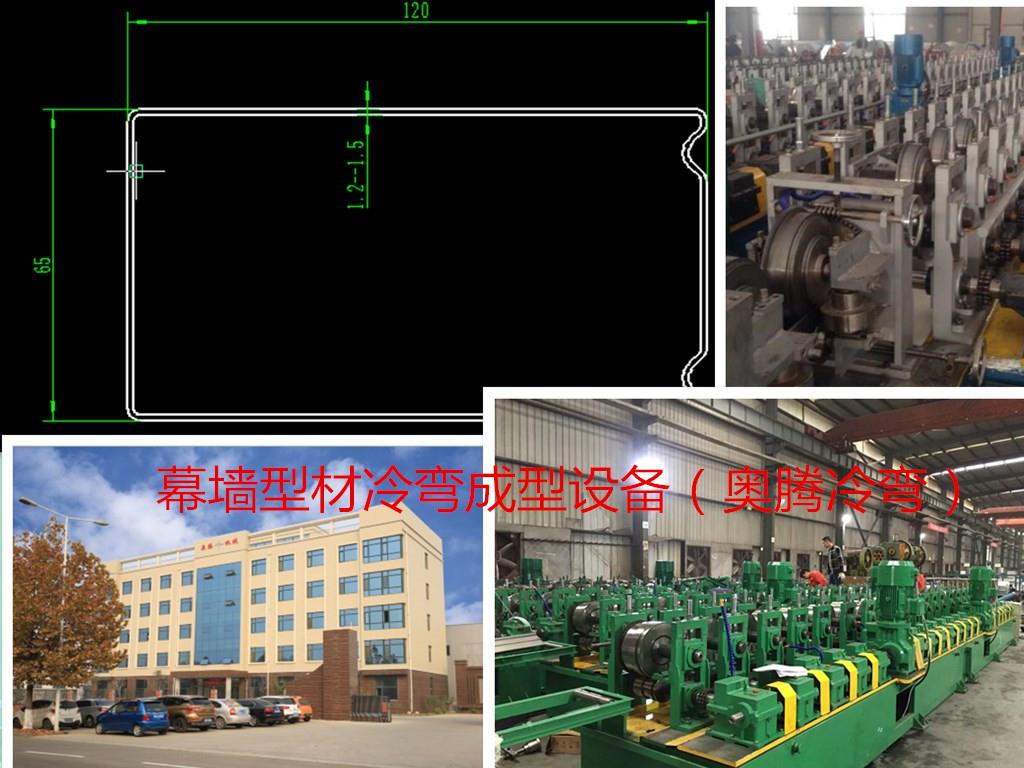

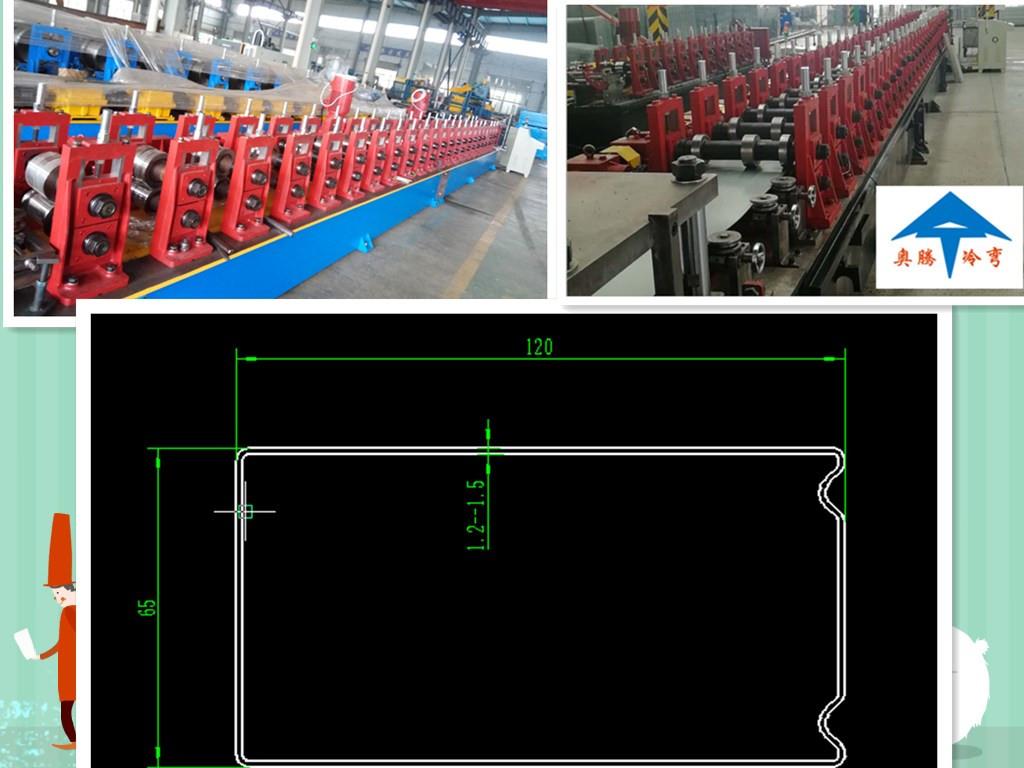

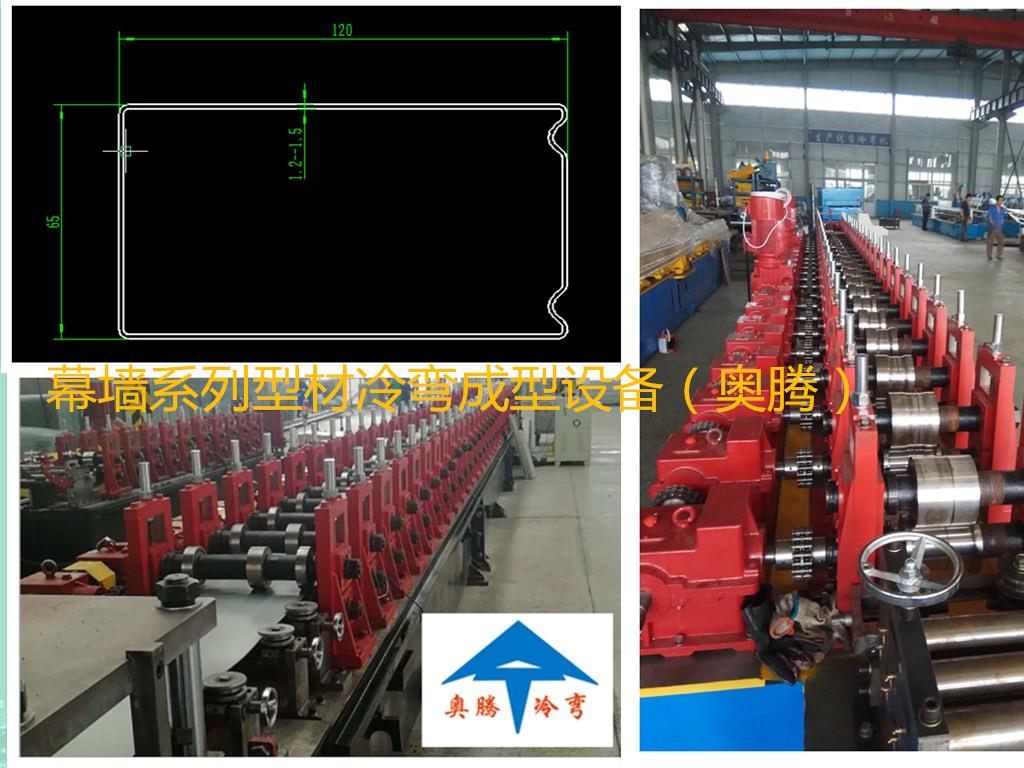

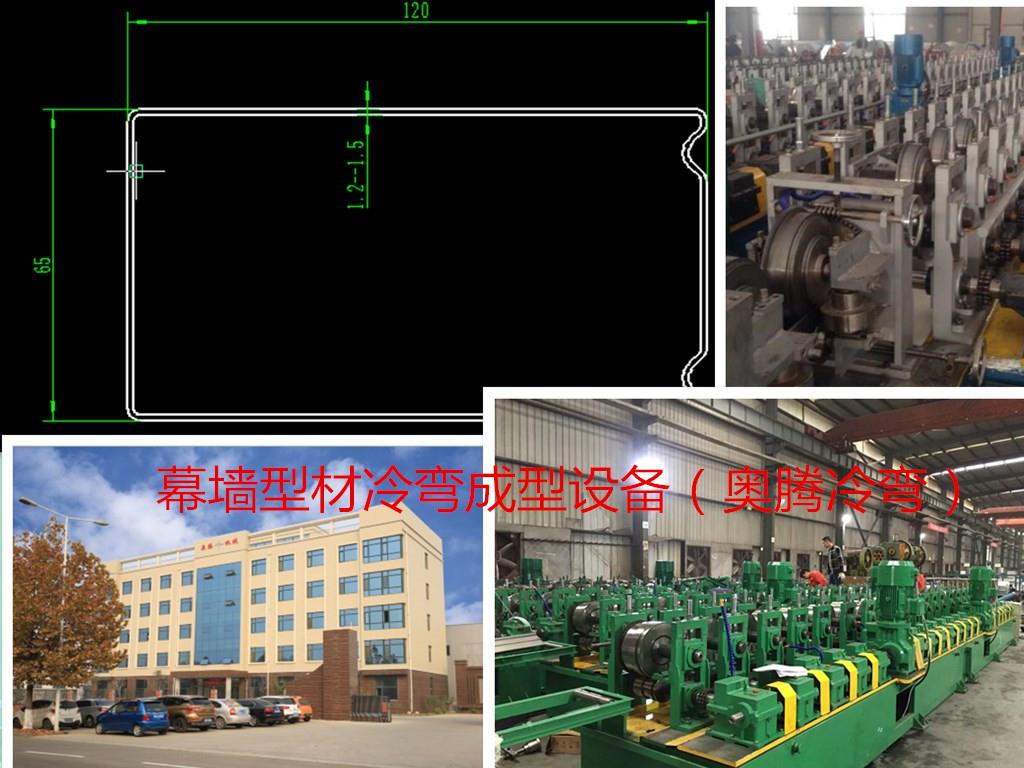

潍坊奥腾冷弯机械有限公司是一家从事各类金属薄板冷弯成型设备制造的老牌企业,幕墙系列型材冷弯成型设备也是我们重点制造的设备之一。

为创造,提高我公司企业度,树立企业形象,我们本着“一切追求高质量,用户满意为宗旨”的精神,以“的价格、周到的服务、可靠的产品质量”的原则向您郑重承诺:

服务宗旨:快速、果断、准确、周到、彻底

服务目标:服务质量赢得用户满意

服务效率:如幕墙系列型材冷弯成型设备出现故障,供方在接到通知后,2小时内做出响应,维修人员在时间达到现场并开始维修。

售后服务组织机构情况及综合实力:

我公司目前有6名,10名,具备完成各类冷弯设备,及与之配套的液压、数控电气的设计、制造能力;组装人员30人,常年在外安装调试及售后服务人员8人且平均售后工龄5年以上。

Weifang Aoteng Cold bending Machinery Co., Ltd. is a professional in all kinds of metal sheet cold forming equipment manufacturing old brand, curtain wall series profile cold bending forming equipment is also one of our key manufacturing equipment.

In order to create famous brands, improve our company's reputation and establish our corporate image, we are guided by the spirit of "pursuing high quality and customer satisfaction", with the spirit of "the most affordable price, the most considerate service". The principle of the most reliable product quality "solemnly promises to you:

Service tenet: quick, decisive, accurate, considerate, thorough

Service objective: service quality wins user satisfaction

Service efficiency: such as curtain wall series profile cold forming equipment failure, the supplier within 2 hours after receiving notice to respond, maintenance staff in the first time to the site and start maintenance.

After-sales service organization and comprehensive strength

Our company currently has 6 senior engineers, 10 professional engineers, with independent completion of all kinds of cold bending equipment, and matching hydraulic, numerical control electrical design, manufacturing capacity; assembly staff of 30 people, Year-round installation and commissioning and after-sales service staff of 8 people and an average after-sale service of more than 5 years.

幕墙系列型材冷弯设备主要参数

操作系统:触摸屏

控制方式:PLC

传动模式:齿轮箱

材料规格:Q235

生产速度:?m

切断方式:液压切断

电压参数:380V/415V,50Hz, 3相

电气控制:PLC

驱动电机:变频电机驱动

钢带宽度:根据客户要求

占地空间: ××(长×宽×高)米

轧辊材质:GCr15 淬火HRC58°-62°

液压油型号:46#液压油

齿轮油型号:18#齿轮油

总电机功率:?kw

切断尺寸公差:≤ ±0.5mm(长≤3000mm)

切断模具材质: Cr12MoV

气源:0.5m?/Min;压力为0.7MPa

Main parameters of Cold bending equipment for Curtain Wall Series profile

Operating system: touch screen

Control mode: PLC

Transmission mode: gear box

Material specification: Q235

Speed of production

Cut off mode: hydraulic cutting

Voltage parameters: 380V/415V, 50Hz, 3 phase

Electrical control: PLC

Drive motor: frequency conversion motor drive

Steel strip width: according to customer requirements

Space: × × (length × width × height) m

Roll material: GCr15 quenched HRC58 °-62 °

Hydraulic oil type: 46# hydraulic oil

Gear oil type: 18 # gear oil

Total motor power: KW

Cut off dimensional tolerance: ≤ ±0.5mm (length ≤ 3000mm)

Cutting mould material: Cr12MoV

Gas source: 0.5mg / min; pressure 0.7MPa

幕墙系列型材冷弯设备的核心部分的轧辊模具,

潍坊奥腾冷弯机械有限公司用的原材料,

遵循科学合理的加工工艺,制造的幕墙系列型材设备经久耐用。

获得了客户的一直**!

基本原理是将钢带通过多道次轧辊模具缓慢变形至幕墙系列型材

设备具有的程度进行控制操作简单,长度可根据需求进行调整切断。

Roll die for the core part of cold bending equipment for curtain wall series profiles,

Weifang Aoteng Cold bending Machinery Co., Ltd. uses high-quality raw materials,

Follow the scientific and reasonable processing technology, the curtain wall series profile equipment durable.

Has won the customer's praise all the time!

The basic principle is to slowly deform the steel strip through the multi-pass roll die to the curtain wall series profile

The equipment has the advanced degree to carry on the control operation simple, the length may carry on the adjustment according to the demand to cut off.

幕墙系列型材设备工艺流程:

上料(人工) —板料校平—冷弯成型—型材校直—切断—卸料(人工)

性能特点:

1.冷弯成型道次布局及设备结构设计科学合理,对带钢软硬程度适应范围广,轧制过程中不会产生波纹、撕裂现象;

2.高安装精度,切断机构,生产率高;

技术参数:

1.生产线长度?米,整机功率约?KW;

2.生产速度?米/min可调;

3.整线PLC控制,彩色触摸屏输入,变频调速;

详细技术参数请致电我们!

Curtain wall series profile equipment process:

Feeding (manual)-sheet leveling-cold forming-profile straightening-cutting-discharging (manual)

Performance features:

1. The cold forming pass layout and equipment structure design are scientific and reasonable, which can adapt to wide range of soft and hard degree of strip, and will not produce ripple and tear phenomenon in rolling process.

2. High installation accuracy, cutting mechanism advanced, high productivity;

Technical parameters:

1. Line length? Meter, the whole machine power about KW;

2. Speed of production? The meter / min is adjustable;

3. Whole line PLC control, color touch screen input, frequency conversion speed regulation;

Please call us for detailed technical parameters!

http://aotengjixie.cn.b2b168.com